As the most widely used disposable medical devices in clinical practice, syringes directly relate to medication safety and patient health. The precision of medical injection molds, the stability of aseptic molding processes, and the verification function of test specimen molds together form the core quality assurance system for syringe production. Combining practical production scenarios, this article systematically elaborates on key technical points and industry trends, providing practical references for medical consumables manufacturing.

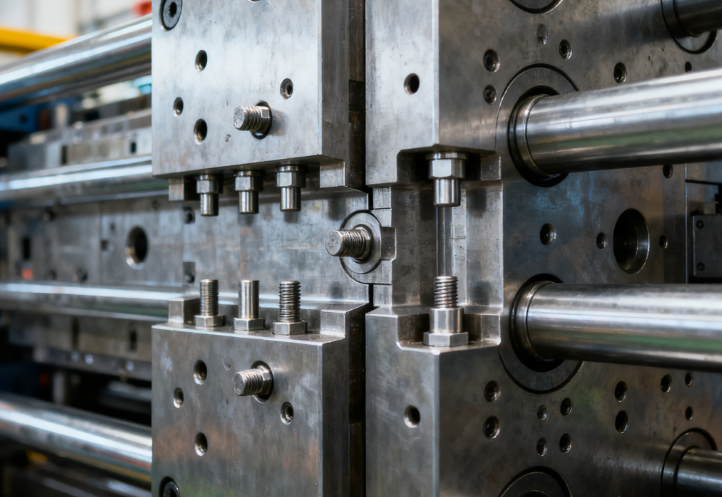

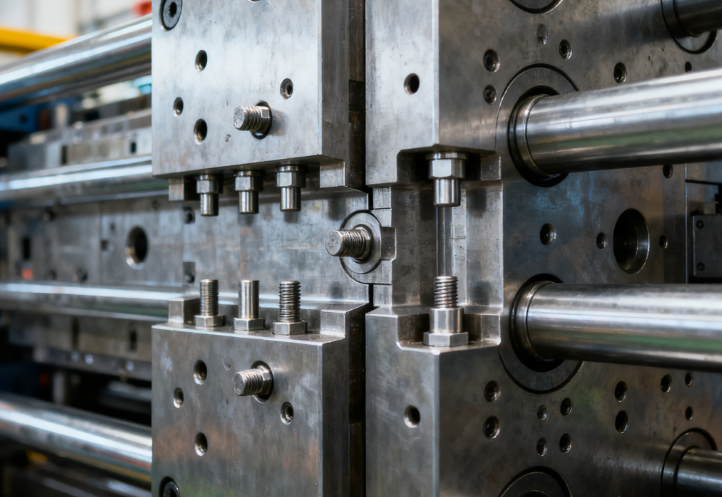

Core structure design focuses on precision and efficiency, adopting 8-32 cavity multi-cavity layout with inter-cavity spacing error controlled within ±0.03mm, and syringe barrel inner diameter tolerance ≤±0.02mm.

Parting surface gap ≤0.01mm with curved fitting design to avoid flash; hot runner system is used for gating with runner diameter of 4-7mm, optimized for balance via mold flow analysis.

Conformal cooling channels are adopted with spacing of 20-30mm, water temperature fluctuation ≤±1℃, and temperature difference between core and cavity controlled above 5℃ to ensure rapid and uniform cooling.

Preferred mold material is S136 stainless steel, achieving hardness of HRC45-48 after treatment, complying with ISO 10993-1 biocompatibility standards, and resisting corrosion after 20 cycles of 121℃ high-temperature sterilization.

Mold surface undergoes mirror polishing with Ra value ≤0.05μm, manufactured by ultra-precision grinding and wire electrical discharge machining with processing accuracy of ±0.001mm.

Production is carried out in ISO Class 8 cleanrooms, with airborne particle (≥0.5μm) concentration ≤352,000 particles/m3, and temperature-humidity stabilized at 22±2℃, 45±5%RH.

Process flow includes four stages: heating and plasticizing, high-pressure injection, holding pressure and cooling, and aseptic demolding, with parameters accurately matched to material properties.

Temperature control follows material adaptation principles: melting temperature of medical-grade PP is 220-270℃, mold temperature is 50-90℃, and cavity surface temperature difference is compressed to ±0.5℃.

Three-stage pressure control is adopted: injection pressure of 1500-1800bar, holding pressure 80% of injection pressure, switching to holding pressure at 95% of full stroke to avoid shrinkage and voids.

Time parameters are set according to product wall thickness: injection time 2-5s, holding time 15-30s, and cooling time accounting for 60%-70% of the molding cycle.

Aseptic assurance measures include raw material sterilization, mold plasma sterilization (microbial residue ≤10CFU/piece), and finished product gamma radiation sterilization (dose 25-40kGy), complying with ISO 11137 standards.

Functionally positioned for pre-production material verification and process optimization, producing test specimens conforming to GB/T 1040.2-2006 (equivalent to ISO 294-1:1996) to reduce mass production risks.

Core application scenarios include material performance testing: tensile strength of medical-grade PP ≥30MPa, elongation at break ≥300% via tensile specimens, and sterilization resistance evaluation (performance loss ≤10% after 20 sterilization cycles).

Used for process parameter verification, adjusting mold compensation via specimen shrinkage test (target ≤0.5%) to ensure finished product dimensional accuracy.

Mold design adopts single-cavity or 4-cavity structure with cavity dimensional tolerance ±0.01mm and draft angle 0.1°-0.2°, adapting to different testing requirements.

Materials include S136 corrosion-resistant mold steel or 38CrMoAl alloy structural steel, with cooling channel spacing 20-30mm and water temperature fluctuation ≤±1℃ to ensure uniform specimen cooling.

Service life meets industry standards: continuous sampling life of polymer material test molds is 5,000-8,000 times, and nitrided molds can reach 20,000-30,000 times, satisfying long-term batch testing needs.

Intelligent production upgrading: adopting AI-supported automated quality control systems, real-time collecting production data via cavity pressure sensors, and controlling dimensional fluctuation within ±0.01mm through IoT technology.

Expansion of biodegradable materials application: polylactic acid (PLA) and poly(lactic-co-glycolic acid) (PLGA) gradually replacing traditional plastics to reduce medical waste pollution.

Breakthrough in micro-nano molding technology: achieving minimum 0.1mm micro-structure molding via micro-EDM to meet high-precision requirements of syringe scale marking and leak-proof structures.

Strengthening of aseptic assurance technology: developing self-cleaning mold surface coatings and popularizing integrated aseptic packaging and molding equipment to eliminate secondary pollution.

The core of syringe production lies in the high precision of medical injection molds, strict control of aseptic molding processes, and accurate verification of test specimen molds. Twenty industry-recognized key data provide clear standards for production, ensuring product dimensional accuracy, sealing performance, and biosafety. With continuous innovation in intelligent, environmentally friendly, and precision technologies, the syringe manufacturing industry is moving towards higher quality, better efficiency, and greater sustainability, providing more reliable consumable support for clinical diagnosis and treatment.