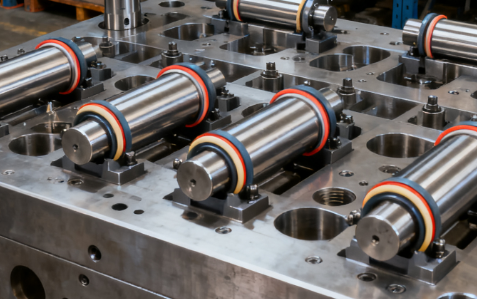

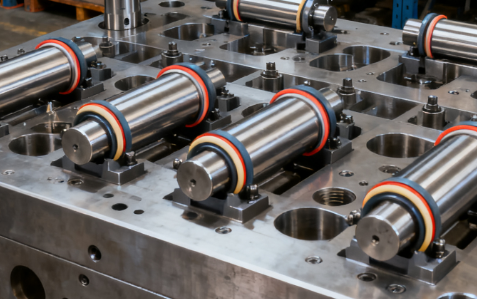

Guide pillars and bushings are core guiding/positioning components of injection molds, directly determining opening/closing precision, operational stability, molded part quality, and service life. In general injection molding, proper selection and installation reduce downtime and boost efficiency. For test specimen molds—requiring high molding consistency and data repeatability—their technical adaptability directly impacts the accuracy of material mechanical property tests (e.g., tensile, impact strength). Currently, with the development of precision injection molding and high-temperature material processing, guide pillars and bushings are evolving towards high precision, long service life, self-lubrication, and intelligence.

Selection should center on mold working conditions, balancing precision, environment, and cost. General molds follow "load adaptation, wear resistance, easy maintenance"; test specimen molds emphasize "high-precision guidance, low friction, stable repeat positioning" to avoid specimen size fluctuations.

Key parameters comply with industry standards:

Fit clearance: H7/h6 fit for general precision molds (0.05-0.08mm); 0.03-0.05mm for test specimen molds; 10%-15% expansion for high-temperature materials (PPS, PEEK).

Dimensions: Guide pillar diameter φ16-φ25mm (general small molds), φ20-φ30mm (test specimen molds); effective length 15-20mm longer than bushings.

Material/hardness: SUJ2 steel for guide pillars (HRC58-62); TD/DLC coating (HV1500+) for test specimen molds; oil-impregnated alloy/self-lubricating composites for bushings.

Tolerances: Guide pillar straightness ≤0.01mm/m, cylindricity ≤50% of dimensional tolerance; coaxiality error ≤0.008mm (test specimen molds).

Test specimen molds prioritize double-section reducing guide pillars (rapid centering + precision positioning) and spiral oil groove bushings. Multi-cavity molds adopt symmetrical layout, with diagonal guide pillars 10%-15% larger to balance lateral force.

Adequate preparation: Clean components and mounting holes; inspect perpendicularity/hole tolerance (symmetry ≤0.01mm for test specimen molds); prepare hydraulic presses, dial indicators, and liquid nitrogen (for cold fitting); preheat high-temperature molds to 50-80℃.

Standard installation steps:

Bushing press-fitting: H7/k6 transition fit, perpendicularity deviation ≤±0.005mm; post-press precision grinding.

Guide pillar installation: Hot/press fit (0.03-0.06mm interference) for general molds; liquid nitrogen cold shrinkage (0.05-0.08mm interference) for test specimen molds; 15° guiding bevel (R3-R5mm).

Adjustment: Uniform clearance (4-point measurement); 100 test runs (no jamming, repeat positioning ≤0.005mm for test specimen molds).

Fixing: M8-M12 anti-rotation pins (≥15mm from parting surface); base plate thickness ≥1.5×guide pillar diameter.

Test specimen mold specifics: One-time clamping for mounting holes; 20-30 test specimens (dimension fluctuation ≤±0.02mm); high-temperature grease + dust rings.

Inspection standards:

Operation: Smooth opening/closing, no eccentric wear, noise ≤75dB.

Precision: Repeat positioning ≤0.005mm (50 runs, laser interferometer); fitting surface contact area ≥80% (blue oil test).

Mold test: Dimensional compliance (100 runs for general molds); test data dispersion ≤3% (test specimen molds).

Maintenance:

Lubrication: 5000 mold cycles (general), 3000 cycles (test specimen molds); high-temperature grease (≤250℃).

Wear monitoring: Replace when guide pillar wear ≥0.1mm or bushing scratches ≥0.05mm.

Intelligent maintenance: Built-in sensors for temperature/vibration monitoring (predictive maintenance).

Technical trends: Integration, intelligence, and maintenance-free designs; self-lubricating coatings (DLC, TiN); extreme condition-adapted (high-pressure, corrosion-resistant) solutions for high-performance material testing.