In the operation of construction machinery, hydraulic systems and cylinders, sealing performance directly determines equipment reliability and service life. As core sealing components, polyurethane seals for construction machinery, hydraulic systems and cylinders rely on the excellent properties of polyurethane materials and targeted structural designs to establish reliable protection under harsh working conditions such as high pressure, reciprocating motion and complex media. These seals not only need to resist hydraulic oil erosion, mechanical friction and pressure impact, but also adapt to extreme temperature fluctuations. Their performance directly affects the operation efficiency, maintenance cost and safety factor of equipment, and has become an indispensable key component in the field of high-end equipment manufacturing.

The designable molecular structure of polyurethane (PU) materials endows the seals with multiple core advantages. Its wear resistance is 5-8 times that of ordinary rubber, which can effectively resist the reciprocating friction loss of piston rods and cylinders and significantly extend the seal life. In terms of mechanical strength, it has outstanding tensile strength and tear resistance, and can maintain structural stability under the conventional working pressure of 40MPa. The enhanced formula with 15% short-cut carbon fiber can further increase the pressure resistance level to 60MPa. It also has good hydrolysis resistance and medium resistance, with a volume swelling rate of less than 5% in petroleum-based hydraulic oil and water-glycol coolant, suitable for most industrial medium environments.

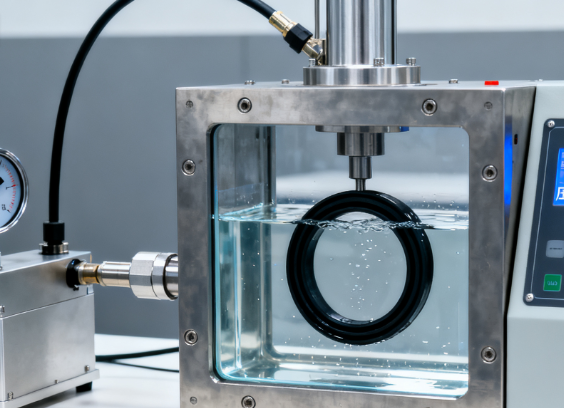

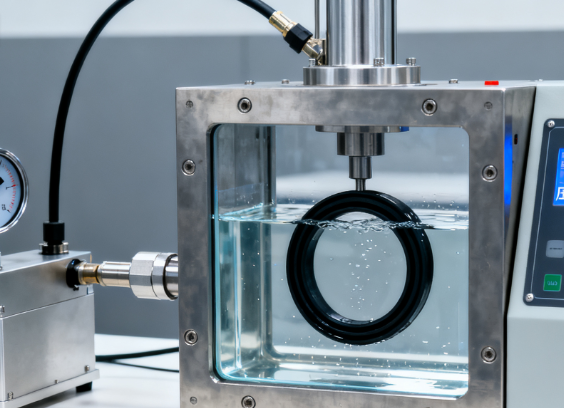

The product adopts a lip-type sealing structure, mainly including Y-type, U-type and other types, with shaft-mounted, hole-mounted and universal designs. Through differentiated structures such as asymmetric lips, equal-height/unequal-height lips, a self-tightening sealing effect is achieved—when the system pressure increases, the medium pressure pushes the lip to closely fit the sealing surface, forming a gradient sealing mechanism. Some products integrate laser micro-texturing technology, and the surface micro-pit design can reduce the friction torque by 40%. It maintains low friction characteristics within the movement speed range of 0.01-1m/s, suitable for the high-frequency reciprocating motion of cylinder pistons.

The temperature adaptability covers the conventional working condition range of -40℃ to 120℃, and special formula products can be extended to -65℃ to 150℃, meeting the needs of extremely cold regions and high-temperature equipment. The compression set rate is less than 15%, and it can still maintain elastic recovery ability under long-term pressure. The seal leakage rate is controlled below 1×10?? Pa·m3/s, meeting the stringent requirements of industrial sealing. The service life of some high-end products can reach 8-12 years, which is more than twice that of traditional rubber seals.

It is widely used in hydraulic systems of equipment such as excavators, loaders and shield machines, focusing on adapting to core components such as boom cylinders and arm cylinders. In the main drive system of shield machines, it needs to meet the stability requirements of large-size seals and resist soil particle pollution and high-pressure grease erosion; in heavy-duty equipment such as mining machinery, it needs to withstand frequent pressure fluctuations and mechanical impacts to ensure continuous operation without leakage. The product must comply with the requirements of GB/T 36520.1-2018 for dimensional tolerances and sealing performance, adapting to the harsh operating environment of construction machinery.

It is suitable for scenarios such as industrial hydraulic stations, hydraulic motors and servo hydraulic systems, undertaking dual responsibilities of static sealing and dynamic sealing. In high-pressure hydraulic systems, it needs to resist instantaneous pressure peaks to prevent seal extrusion failure; in precision servo systems, the low friction coefficient characteristic can avoid affecting system control accuracy. For different media such as water-based and oil-based media, special formulas such as polyether-type and polyester-type can be selected. Among them, polyether-type polyurethane seals have better hydrolysis resistance, suitable for hydraulic systems in humid environments.

As a key sealing component for cylinder pistons and piston rods, it directly determines the output efficiency and stability of cylinders. In standard cylinders, it is necessary to strictly match the seal groove size and follow the ISO 3601-1 Class A tolerance standard; in non-standard customized cylinders, personalized production can be realized through mold-free processing technology. In hydraulic brake cylinders of new energy vehicles, it needs to meet the requirements of lightweight and long service life, with an average of 15-20 polyurethane seals equipped per high-end vehicle; in energy storage equipment cylinders, it needs to adapt to high-pressure working conditions, and a single 100MWh energy storage project requires about 5,000 seals.

In terms of material innovation, self-healing polyurethane materials have entered the laboratory stage, which can realize 3 times of micro-crack autonomous repair and are expected to be mass-produced in 2026; the graphene composite formula reduces the friction coefficient to 0.08, suitable for precision hydraulic systems. Process upgrading focuses on intelligent manufacturing. The combination of servo hydraulic molding and AI visual inspection increases the one-time pass rate of products to 98.5%, and the digital twin platform realizes real-time optimization of process parameters. Intelligent operation and maintenance has become a new direction. The AI life prediction model based on wear data has an accuracy rate of 95%, which can early warn the replacement cycle.

In the production link, it is necessary to strictly control the material formula, and the hard segment content should be maintained in the range of 35%-42% to ensure that the microphase separation scale meets the performance requirements. Online detection technology is adopted in the processing process, and the product uniformity is controlled through near-infrared and terahertz detection methods. During installation, it is necessary to ensure that the seal groove is clean and free of burrs to avoid lip damage; the assembly gap should be controlled within a reasonable range to prevent extrusion failure under high pressure. The storage environment should be kept dry and ventilated, avoiding direct sunlight to prevent material aging.

Current industry standards include GB/T 36520.1-2018, GB/T 36520.3-2019, etc., which regulate dimensional tolerances and performance testing requirements. With the advancement of the high-end equipment independent and controllable strategy, the localization rate of domestic high-performance polyurethane seals has increased to 70%, an increase of 32 percentage points compared with 2020. In the future, the industry will develop towards material-structure-function integration, and recycling and regeneration technology and full life cycle cost control will become the focus of competition, promoting the industry to shift from cost-oriented to high-quality development with equal emphasis on value and resilience.