Technical Analysis of Rubber Dynamic Performance, Rubber Medium Resistance and Rubber Fatigue Test Molds

1. Core Technical Dimensions of Test Molds

1.1 Material Selection & Design

Mold Body: 4Cr13 martensitic stainless steel (HRC 50-55) is industry-standard, offering corrosion/wear resistance for long-term dimensional stability. Tungsten carbide inserts reduce wear rate by over 80% in high-dynamic-load cavity areas.

Sealing & Wear Parts: Fluororubber O-rings (-20℃~200℃, oil expansion <15%) and silicon nitride ceramic guide pillars ensure sealing reliability and motion accuracy under 10Hz high-frequency reciprocation.

1.2 Mold Structure & Process Innovation

1.2.1 Rubber Dynamic Performance Test Molds

Adopt eccentric wheel-connecting rod loading (5Hz~100Hz, ±1% load accuracy) and axisymmetric double-station design. Enables simultaneous testing of rubber sample stiffness/damping, boosting efficiency by 50%.

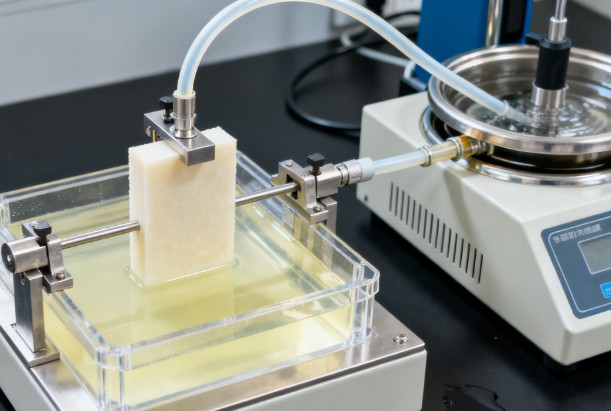

1.2.2 Rubber Medium Resistance Test Molds

Integrate medium circulation-temperature control system (±2℃ accuracy, 0.1MPa~2MPa pressure). Full-immersion sealed cavity ensures full contact between rubber sample and medium, ideal for coolant/fuel resistance testing.

1.2.3 Rubber Fatigue Test Molds

Equipped with servo-hydraulic loading units (0~50kN, customizable sine/square waves) and built-in strain monitoring. Supports full-life testing of rubber parts (low-cycle high-load to high-cycle low-load) and tracks fatigue mechanical response.

1.3 Process Adaptation & Technical Trends

Precision Machining: Five-axis CNC machining (Ra ≤ 0.4μm) ensures uniform rubber sample stress; vacuum heat treatment improves mold mechanical consistency by 30%.

Intelligence: IoT sensors (temperature/pressure/vibration) enable real-time mold monitoring and cloud-based rubber test data analysis, driving digitalization of rubber testing.

2. Practical Production Applications

2.1 Automotive Industry

Rubber dynamic performance molds: Verify engine mount stiffness (-40℃~120℃, 10Hz~50Hz).

Rubber medium resistance molds: Simulate coolant/fuel erosion on seals.

Rubber fatigue molds: Test door seal strip durability (1M+ cycles). A leading automaker reduced early failure rate by 40% and shortened R&D by 25%.

2.2 Aerospace Field

Dynamic molds: Test aircraft door seal stability (30Hz~80Hz vibration).

Medium resistance molds: Evaluate hydraulic oil/aviation kerosene impact.

Fatigue molds: Assess seal life during hundreds of take-off/landing cycles.

2.3 Rail Transit

Dynamic molds: Measure shock pad damping (5Hz~30Hz track vibration) for ride comfort.

Medium resistance molds: Simulate rain/oil erosion on rubber parts.

Fatigue molds: Verify shock pad durability under 10M+ train passes.

3. Conclusion

These molds enable accurate testing of key rubber properties via material upgrades, structural innovation and process optimization. They are evolving toward multi-physics coupling, intelligent control and lightweight design. Future integration with 5G/Industrial Internet will further automate rubber testing, supporting high-end rubber product development.