Rubber Tensile Test Molds, Rubber Hardness Test Molds, and Rubber Compression Set Test Molds Hooren Mold

In the quality control and performance verification of rubber materials, rubber tensile test molds, rubber hardness test molds, and rubber compression set test molds are three core types of equipment. They are widely used in scenarios such as medical rubber testing, automotive seal testing, and O - ring testing, directly determining the accuracy of test data and the stability of product quality.

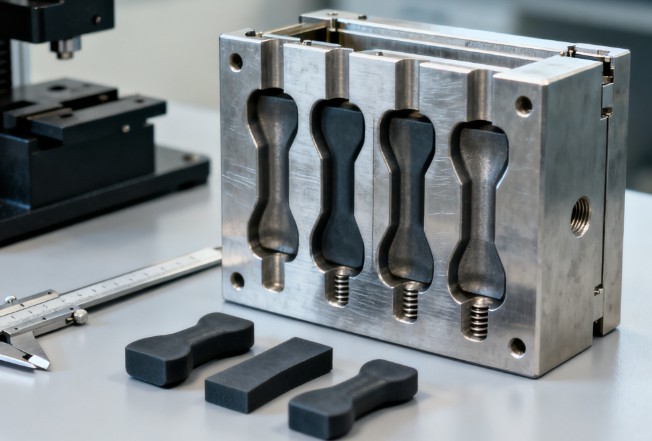

1. Rubber Tensile Test Molds

Rubber tensile test molds detect key properties like tensile strength and elongation at break, evaluating rubber's tear and fatigue resistance.

1.1 Standard Compliance

They follow mainstream standards:

GB/T 528 - 2009: Fit dumbbell - shaped Type 1 (115mm total length, 25mm working section) and Type 2 (75mm total length, 12.5mm working section) specimens, with cavities matching the 25mm/12.5mm arc.

ASTM D412: Work for dumbbell - shaped and right - angle specimens (1–6mm thick), with 0.2mm rounded working section edges to avoid fracture deviation.

ISO 37:2017: Require cavity surface roughness (Ra ≤ 0.8μm) for precision rubber testing.

1.2 Core Structure

Cavity Layout: Single or multi - cavity (4–6 cavities), with ≥15mm spacing for even heat during vulcanization.

Exhaust & Demolding: 0.1–0.2mm - wide exhaust grooves at cavity ends remove vulcanization gas. Guide pillars (±0.01mm tolerance) and 3–5mm ejector pins (evenly in non - working sections) ensure damage - free demolding.

1.3 Applications

Medical: Test infusion tube silicone and seals, ensuring burr - free, smooth specimens.

Automotive: Mass - produce engine gaskets/rubber strips with multi - cavity molds for efficient tensile testing.

Industrial: Adapt to O - rings/conveyor belt rubber by adjusting cavity size.

2. Rubber Hardness Test Molds

Rubber hardness test molds prepare specimens for Shore A/D hardness tests, ensuring flat, stress-free samples.

2.1 Standard Compliance

GB/T 531.1 - 2008: Specimens (≥6mm thick, ≤3 layers, ≥15mm diameter) need ±0.1mm cavity thickness tolerance and ≤0.02mm flatness.

ASTM D2240 - 2022: Allows 3–6mm thin specimens with positioning rings (thickness noted in reports).

ISO 7619 - 1:2018: Cavity edges have 0.5mm chamfers to prevent specimen cracking.

2.2 Core Structure

Cavity: Circular/square flat-bottomed (e.g., 7mm deep for 6mm specimens), precision-ground for flatness.

Mold Closing & Demolding: Double guide pillars + positioning pins (≤0.005mm gap) ensure alignment. Ejector pin density varies: multiple thin pins for soft rubber, fewer thick pins for hard rubber.

2.3 Applications

Consumer Goods: Single-cavity molds test Shore A hardness of erasers/yoga mats for small batches.

Seals: Custom annular cavities test Shore D hardness of O-rings/flange gaskets.

Electronics: Thin-cavity molds with positioning rings test gaskets’ hardness for sealing/buffering.

3. Rubber Compression Set Test Molds

These molds simulate long-term compression to assess rubber rebound, critical for seals/shock absorbers’ lifespan.

3.1 Standard Compliance

GB/T 7759 - 2015: Fits cylindrical (φ29mm×12.5mm) or square (12.5mm×12.5mm×25mm) specimens, using 25% compression limit blocks (9.375mm height).

ISO 815 - 1:2018: Adjustable specimen height (10–20mm) and compression rate (25%/50%) via replaceable blocks.

ASTM D395 - 2023: High-temperature molds have built-in temperature sensors for real-time monitoring.

3.2 Core Structure

Sealing & Heat Resistance: Silicone seals prevent flash; split design (heat-resistant cavity, ordinary mold base) handles -60~500℃.

Stress Uniformity: 0.05mm convex cavity bottom ensures even compression, ideal for precision seals.

3.3 Applications

Auto Shock Absorption: Tests engine/chassis shock absorbers (150℃ high-temp tests) for rebound.

Refrigeration: Tests door gaskets/seals for normal-temperature compression set.

Industrial Pipelines: Verifies chemical pipe seals’ rebound in oil-resistant/high-temp environments.

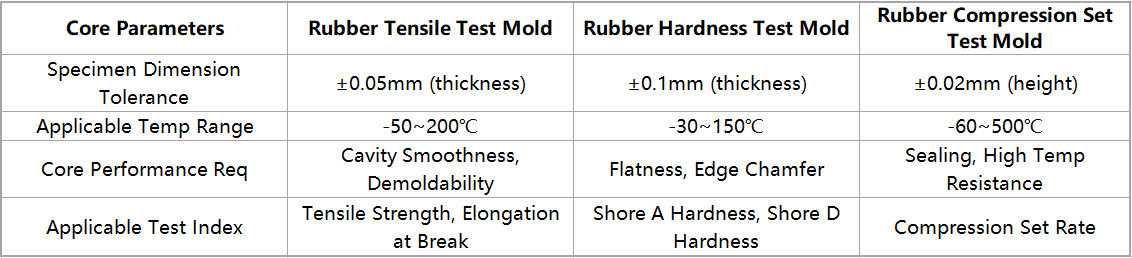

4. Comparison of Core Parameters of the Three Types of Molds

5. Daily Maintenance and Usage Precautions

After each use, wipe the cavity with alcohol to remove rubber debris. Let high - temperature molds cool naturally to room temperature before disassembly. Regularly apply high - temperature - resistant grease (e.g., molybdenum disulfide grease) to moving parts like guide pillars and ejector pins. Calibrate cavity size and flatness quarterly.

Conclusion

Rubber tensile, hardness, and compression set test molds are core for rubber performance testing. Their design and adaptability determine test validity. Select molds as per standards and products, and maintain them well to ensure accurate quality control for rubber products in medical, automotive, and industrial fields.