Key points of food-grade plastic mold processing

In the booming food industry today, the processing quality of food-grade plastic molds directly relates to food safety and

consumer health. With technological advancements and increasing emphasis on food safety, the key points for processing

food-grade plastic molds are continuously updated and improved.

1. Material Selection

Choosing materials for food-grade plastic molds is fundamental to ensuring food safety. Selected materials must pass strict

food safety certifications, such as FDA (U.S. Food and Drug Administration) certification and EU 10/2011 (Regulation on Food

Contact Materials).

Stainless Steel: 304 and 316L stainless steels, with excellent corrosion resistance, high strength, and stability, are widely used

in molds requiring high hygiene standards (e.g., beverage bottle blow molds, food tray injection molds). Their smooth surfaces

resist bacterial growth and withstand high-temperature sterilization.

Food-Grade Plastics: Polypropylene (PP) and polyethylene (PE) are common. PP, heat-resistant (100-120°C), chemical-resistant,

non-toxic, and odorless, is used for food containers and tableware molds. PE, flexible and impact-resistant, suits molds for

flexible products like plastic films. Material selection depends on food properties (acidity, temperature).

Silicone: With outstanding temperature resistance (-40 to 230°C), flexibility, and non-toxicity, silicone is ideal for cake and

chocolate molds. It reproduces complex shapes accurately and enables easy demolding.

2. Mold Design

Structural Design: The design must consider molding processes and demolding needs. For injection molds, runner systems

should ensure uniform, rapid melt filling to reduce weld lines (which affect strength and surface quality). Hot runner systems

minimize waste and prevent contamination. Demolding mechanisms must be reliable to avoid product damage or residue.

Surface Treatment: Mold surfaces require high smoothness (roughness ≤ Ra0.4μm) to reduce food adhesion and facilitate

cleaning. Polishing and electroplating (e.g., chrome plating) enhance surface hardness, wear resistance, and chemical stability.

Dimensional Accuracy: Tolerances are typically ±0.05mm (±0.01mm for high-precision products like pharmaceutical bottles).

Shrinkage of plastic materials is compensated for in design, with high-precision equipment (CNC machining centers, CMMs)

ensuring accuracy.

3. Processing Techniques

Machining: High-precision milling and grinding ensure accuracy and surface quality. 5-axis CNC machining centers handle complex

curved surfaces with ±0.005mm precision. Burrs and debris are avoided, and molds are thoroughly cleaned post-processing.

EDM (Electrical Discharge Machining): Used for complex shapes, with controlled parameters to avoid excessive heat-affected layers.

Surfaces are polished to remove discharge marks.

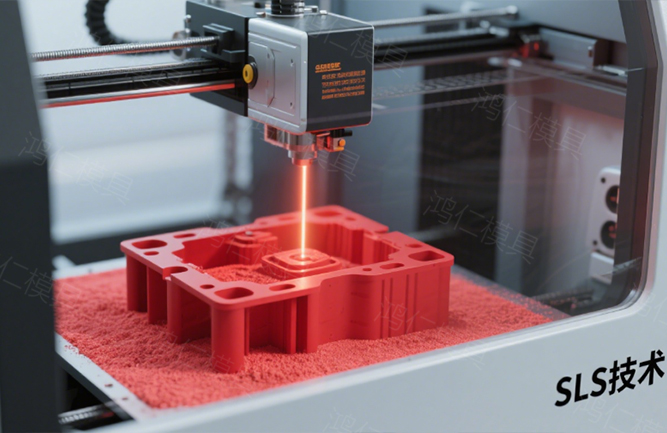

Rapid Prototyping: 3D printing (e.g., SLS) accelerates mold development by creating prototypes for testing. While limited by strength

and surface quality, it suits specific applications.

4. Quality Inspection and Control

Material Testing: Materials are tested for chemical composition, hardness, physical/thermal properties, and hygiene indicators

(heavy metals, migration) before processing.

In-Process Inspection: Critical dimensions and surfaces are checked using precision tools (calipers, CMMs) to ensure compliance

with tolerances. Weld quality is inspected for internal defects.

Final Inspection: Finished molds undergo dimensional, surface, and performance tests. Injection molds are trial-run to check

operation, molding quality, and demolding. Only passing molds are delivered.

In the new era, food-grade plastic mold processing integrates traditional practices with new technologies to meet stricter safety

standards. From eco-friendly materials to intelligent, high-precision processes and automated inspections, every improvement

safeguards the food industry’s safe development.