A Concise Guide to Common English in Plastic Mold Industry

Ⅰ. Basic Terms in Mold Design

Parting Line (PL): The contact surface between the front mold and rear mold when the mold is closed, determining the product's demolding direction.

Draft Angle: A small inclination angle (usually 0.5°–3°) between the mold surface and demolding direction for easy demolding.

Gate: The channel for plastic melt to enter the mold cavity (common types: pin gates, side gates, etc.).

Runner: The channel connecting the gate and sprue, guiding melt flow.

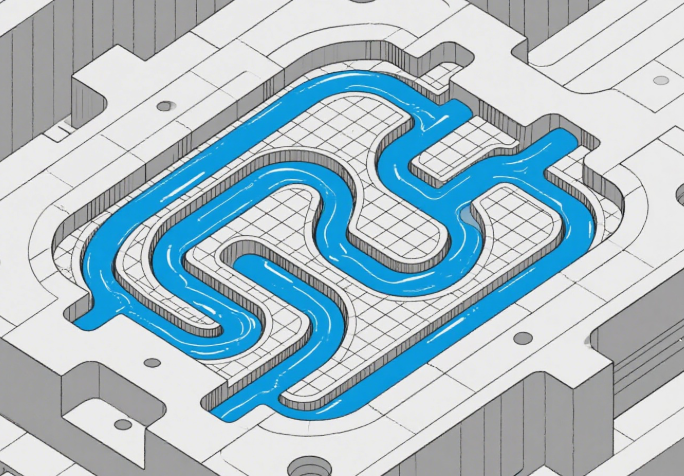

Cooling Channel: The passage inside the mold for cooling, controlling the molding temperature.

Venting Groove: A groove for exhausting air from the cavity to avoid molding defects.

Ⅱ. Mold Structural Components

Core/Cavity: Key components for direct product molding, divided into core (male mold) and cavity (female mold).

Ejector Pin: A cylindrical part for ejecting molded products (typical diameter: Φ2mm–Φ12mm).

Ejector Sleeve: An ejector pin with a sleeve, used for ejecting annular or thin-walled products.

Slide: A movable component for molding product undercuts or side holes.

Lifter: An inclined-motion ejector mechanism for handling internal undercuts of products.

Locating Ring: Installed on the mold faceplate to align the mold with the injection machine nozzle (common diameters: Φ100mm–Φ200mm).

Guide Pin/Bushing: Guide components ensuring precise positioning during mold opening/closing.

Hot Runner System: Includes hot sprue, manifold, and temperature controller, reducing material waste.

Ⅲ. Processing Terms

Electrical Discharge Machining (EDM): Uses electrical discharge erosion to machine complex shapes (common electrodes: copper/graphite).

CNC Milling: Cuts mold steel via computer-controlled tools (accuracy: up to ±0.01mm).

Wire Cut EDM: Uses a metal wire as an electrode to cut workpieces, suitable for complex contour machining.

Grinding: Polishes the mold surface with a grinding wheel to improve precision and finish.

Polishing: A process to improve mold surface roughness (mirror polishing achieves ultra-high finish).

Additive Manufacturing (AM): E.g., Direct Metal Laser Sintering (DMLS), used to make special structures like conformal cooling channels.

Ⅳ. Injection Molding Process

Mold Flow Analysis: Simulates plastic flow via software to optimize gate position and cooling systems.

Injection Pressure: The pressure pushing plastic melt into the mold cavity.

Hold Pressure: Pressure maintained after injection (compensates for plastic shrinkage, usually 60%–80% of injection pressure).

Injection Speed: The speed of melt entering the cavity (impacts molding quality).

Melt Temperature: The temperature of molten plastic (varies by material type).

Mold Temperature: The mold’s operating temperature (controlled by the cooling system).

Cycle Time: Total time for one injection cycle (includes injection, holding, cooling, and ejection stages).

Ⅴ. Quality Defects and Inspection

5.1 Common Defects

Sink Mark: Surface depression caused by uneven local cooling.

Weld Line: A linear defect at the confluence of two plastic melts.

Flash: Flash caused by excessive mold clearance (typical allowable value: ≤0.05mm).

Air Bubble: Bubbles from trapped air in the cavity or material decomposition.

Burn Mark: Plastic carbonization due to local overheating.

Warpage: Product deformation from uneven stress after cooling.

5.2 Inspection Terms

Tolerance: Allowable dimension variation (per ISO 77154, graded MT1–MT5).

Surface Finish: Expressed by Ra value (mirror polishing: Ra ≤0.025μm; EDM surface: Ra ≈1.6–3.2μm).

Coordinate Measuring Machine (CMM): Equipment for precision product dimension measurement.

Ⅵ. Industry Standards and Specifications

ISO 77154: Specifies marking methods and general tolerance values for injection-molded part dimensions/geometric tolerances.

ASTM D5948: Test standard for thermosetting molding compounds (covers multiple performance indicators).

Euromap 63/SPI: Data interaction protocol between injection machines and host computers (supports parameter monitoring/remote control).

Ⅶ. Common Materials and Properties

Mold Steel: E.g., S136 (corrosion-resistant mirror steel), 718H (pre-hardened steel), H13 (hot-work mold steel).

Plastic Material: E.g., PP (Polypropylene), ABS (Acrylonitrile-Butadiene-Styrene copolymer), PC (Polycarbonate).

Hardness: Mold steel hardness is commonly expressed by HRC (Rockwell Hardness C Scale) (e.g., Cr12MoV reaches HRC58–62).

Ⅷ. Commonly Used Abbreviations Table

| Abbreviation | English Full Name |

|---|---|

| IM | Injection Mold |

| CAD | Computer-Aided Design |

| CAM | Computer-Aided Manufacturing |

| CAE | Computer-Aided Engineering |

| CNC | Computer Numerical Control |

| EDM | Electrical Discharge Machining |

| PVD | Physical Vapor Deposition |

| HRC | Rockwell Hardness C Scale |

| CMM | Coordinate Measuring Machine |

| PL | Parting Line |