The differences between two-color molds and ordinary molds

1. Mold Structure

(1)Standard Molds: Basic "Single-Cavity" Design

Standard molds have a simple structure, consisting mainly of a fixed mold (mounted on the injection machine’s fixed platen,

with a gating system to deliver molten plastic) and a moving mold (equipped with an ejection mechanism to release finished

parts). Designed for "single cavity + single material," they produce monochromatic or single-material parts in one injection cycle.

Example: Molds for plastic hangers use a basic cavity to inject polypropylene, forming simple monochromatic products efficiently.

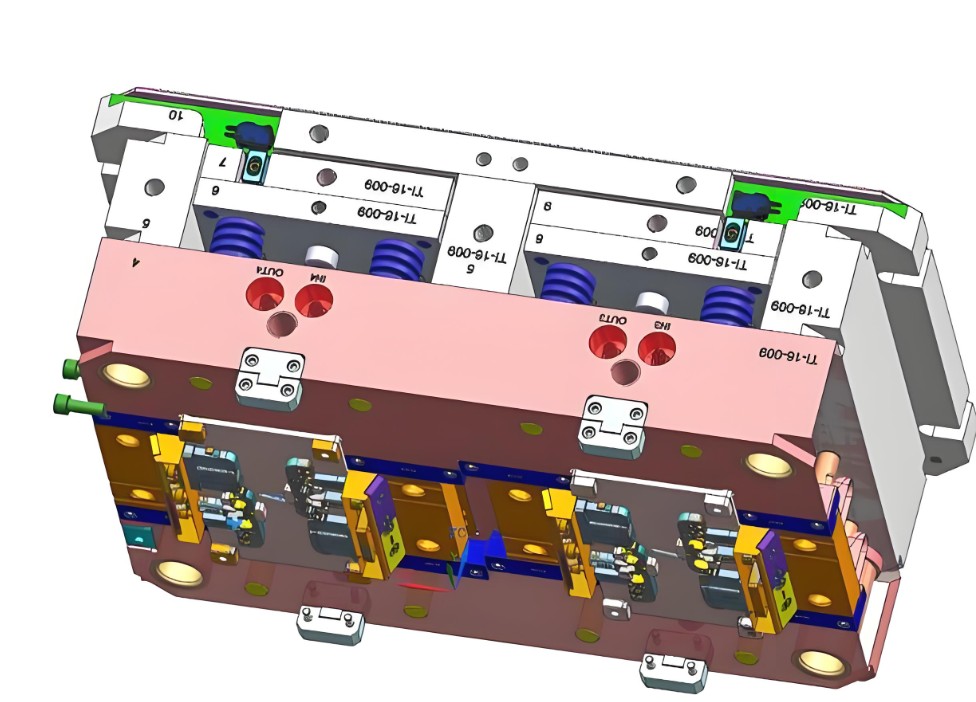

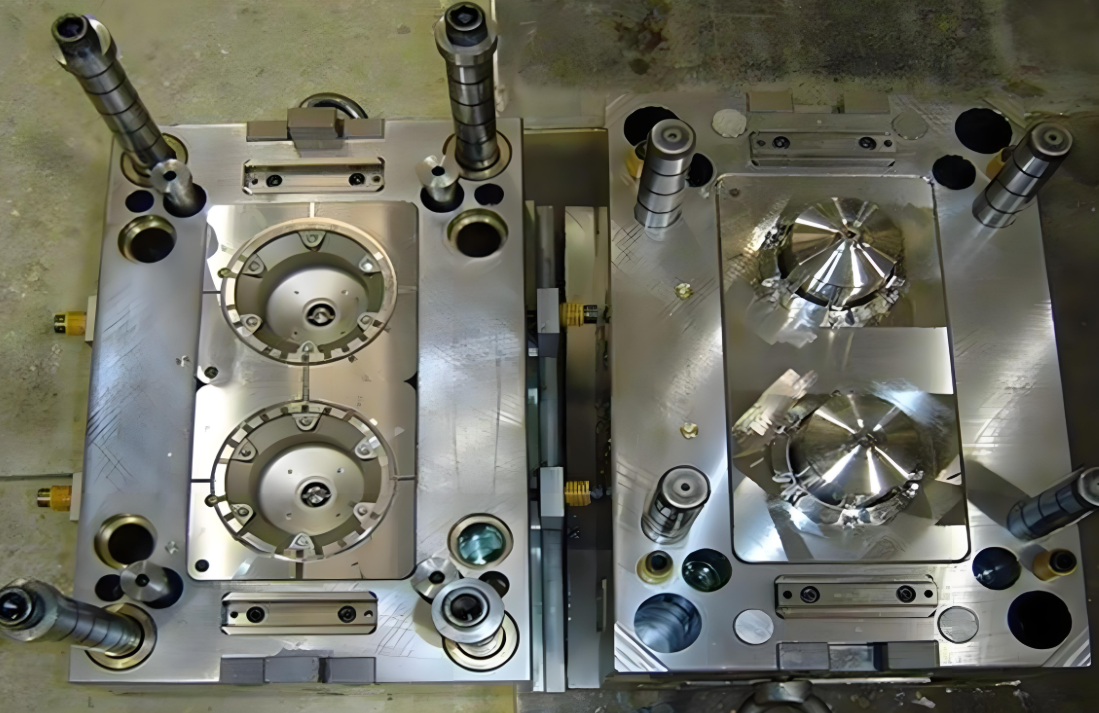

(2)Two-Color Molds: Complex "Multi-Unit Collaboration" Design

Rotary two-color molds: Equipped with two injection units and a rotatable mold plate. First, the first material is injected to form

part of the product; then the plate rotates precisely, and the second material is injected to bond with the first, achieving integrated

two-color molding.

Stacked two-color molds: Two cavities are stacked vertically, with specialized runners to inject different materials sequentially.

Example: Molds for automotive interior two-color buttons create "hard frame + soft button" regions, enhancing both aesthetics

and tactile experience through multi-material integration.

2. Molding Process

(1)Standard Molds: Simple, Controllable Parameters

Standard molding involves a straightforward process: molten plastic is injected into the cavity via the screw and gating system,

followed by packing, cooling, and ejection. Only one material is used, with easy control over parameters (temperature, pressure,

speed). It focuses on stable production of standardized products like daily necessities.

Example: Plastic storage boxes use fixed parameters (e.g., 220–270°C for PP) for consistent monochromatic output.

(2)Two-Color Molds: Multi-Stage Synergy, Precision Timing

Timing control: After the first injection, the mold plate must rotate within a narrow window (0.1-second precision) while the first

material is semi-molten, ensuring strong bonding with the second material.

Material compatibility: Matching shrinkage rates and melting points (e.g., ABS and TPE) to avoid delamination or cracking.

Example: High-end phone cases with "hard PC frame + soft TPU buttons" rely on precise control of injection volume, packing time,

and rotation angle (≤1° error) for flawless integration.

3. Production Efficiency and Cost

(1)Standard Molds: Stable Single Production, Low Changeover Efficiency

Standard molds perform well for monochromatic parts but require time-consuming mold changes (30–60 minutes) for multi-color

production, reducing equipment utilization. They are less cost-effective for small-batch, multi-color orders.

(2)Two-Color Molds: Integrated Production, Cost Savings at Scale

Though two-color molds cost 2–5 times more to design and manufacture, they eliminate mold changes and assembly steps by

producing multi-color/ material parts in one cycle. For example, two-color phone cases skip "injection + assembly" steps, cutting

production time by 40–60% for large batches, making them ideal for high-end industries.

4. Applications and Trends in the New Era

Standard molds dominate daily necessities and basic industrial parts, focusing on "affordability and standardization," enhanced

by smart monitoring for stability.

Two-color molds thrive in electronics, automotive, and medical fields, enabling "aesthetic diversity and functional" (e.g., color-

coded medical tools). Driven by smart manufacturing, they leverage AI design and 5-axis machining (0.001mm precision) to meet

personalized, high-quality demands.

In summary, the choice between two-color and standard molds depends on product requirements, production scale, and budget.

As manufacturing evolves, standard molds will optimize cost-efficiency, while two-color molds will lead in high-end customization,

collectively advancing the injection molding industry.