What is mold opening

1. Definition of Mold Making

Mold making is a systematic engineering process that transforms product designs into molds and auxiliary equipment, encompassing both design and manufacturing (known as "toolmaking" or "tooling" in the industry). It has two practical meanings: first, the development and production of mold(s); second, the opening action of molds during production, opposite to mold clamping.

Mold making is a key hub in industrial production and a prerequisite for mass, standardized manufacturing. Whether for plastic products or metal components, production relies on mold making. The quality and efficiency of mold making directly affect product quality, costs, and time-to-market, impacting enterprise competitiveness. It plays an irreplaceable role in numerous industries such as automotive, electronics, and home appliances.

2. Mold Making Process

2.1 Demand Analysis and Product Design

Demand analysis is the foundation, requiring clarification of product functions, appearance, dimensions, materials, etc., to determine mold type. For example, electronic device casings must consider strength and shielding, while food-contact products need safe materials. Production volume and process feasibility are also evaluated comprehensively.

Product design uses CAD software to build 3D models, considering draft angles and shrinkage rates. An unreasonable draft angle may cause difficulty in demolding. Plastic shrinkage rates range from 0.5% to 3%, so designs must reserve shrinkage allowances, while also considering product assembly and usage scenarios.

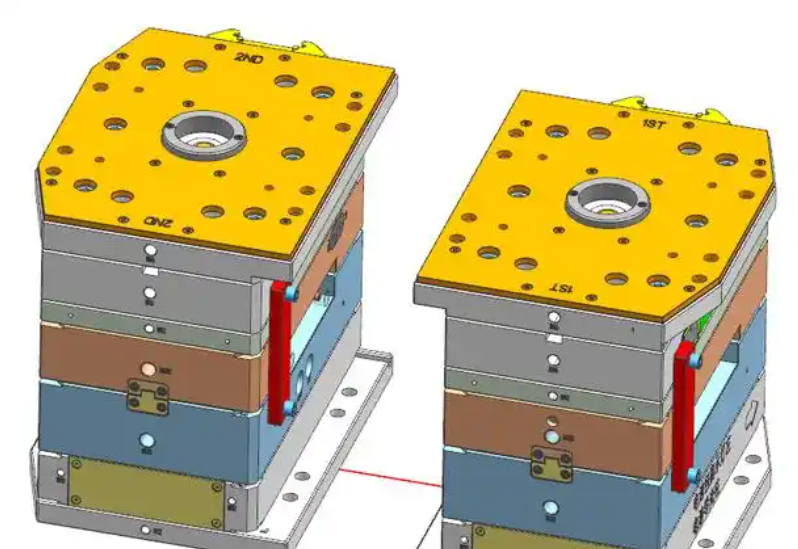

2.2 Mold Design

Mold design is core, involving parting surfaces, runner systems, cooling systems, etc. Parting surfaces affect demolding and quality; runners ensure smooth material filling; cooling systems control temperature to shorten cycles. Demolding and venting systems are also essential for molding. CAE software is used for simulation analysis during design.

2.3 Mold Manufacturing

High requirements for equipment and processes, using CNC machining centers, EDM, etc. Materials include steels like P20 (for general plastic molds) and H13 (for die-casting molds). Manufacturing involves rough and finish machining to ensure precision and surface quality (high-precision molds achieve roughness below Ra0.02μm), with multiple inspections during processing.

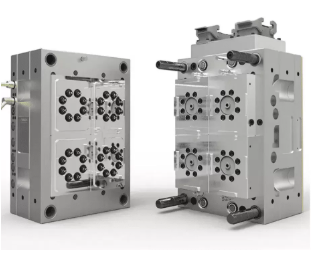

2.4 Mold Assembly and Debugging

Components are assembled precisely, controlling fit accuracy (e.g., parting surface clearance within 0.01mm). After assembly, debugging is done: during test runs, sample quality is observed, and molds are adjusted (e.g., modifying runners, adjusting cooling parameters) until qualified products are produced, often requiring repeated attempts.

2.5 Mass Production and Maintenance

Regular maintenance during mass production includes cleaning, wear inspection, and lubrication. Good maintenance can extend mold life by 2-3 times, reducing costs and improving efficiency. Maintenance records are archived for future improvements.

3. Mold Making Technologies

3.1 CNC Machining Technology

Widely used and upgraded: 5-axis machining centers handle complex curved surfaces with ±0.005mm precision; high-speed machining shortens cycles by 30%-50%. Combined with CAM software for path optimization, it reduces manual intervention and improves consistency.

3.2 3D Printing Technology

Innovative for rapid prototyping, shortening development cycles. It can produce complex molds (e.g., conformal cooling channel molds) to reduce molding cycles by 20%-40%, suitable for small-batch production with materials like resins and metal powders.

3.3 Hot Runner Technology

Common in injection molds, achieving over 95% material utilization, reducing defects, and shortening cycles. Precise temperature control is needed to avoid material decomposition, suitable for mass plastic production.

3.4 Mold Surface Treatment

Enhances performance: nitriding extends life by 2-3 times; hard chrome plating improves smoothness and corrosion resistance; nano-coatings reduce demolding force by over 40%. Processes are selected based on material and usage scenarios.

4. Mold Making Materials

4.1 Mold Steels

Widely used: P20 (pre-hardened plastic mold steel, for daily necessities); 718 (higher performance, for high-surface molds); S136 (corrosion-resistant, for medical devices). Steels undergo strict smelting and heat treatment for stability.

4.2 Aluminum Alloys

Lightweight, good thermal conductivity, and low processing costs, suitable for low-volume, short-life molds (e.g., toy molds) to reduce initial investment.

4.3 Other Materials

Copper alloys (good thermal conductivity/corrosion resistance, for rubber molds); ceramics (for high-precision micro-molds); titanium alloys (for aerospace, high cost but superior performance), meeting special industry needs.