The core difference between three-board molds and two-board molds

In modern manufacturing, injection molds play a crucial role in determining product quality, production efficiency, and cost control. As the two most common types of injection molds, two-plate and three-plate molds exhibit significant differences in structure, working principles, applications, and cost-effectiveness. A clear understanding of these differences is vital for enterprises to optimize their production processes.

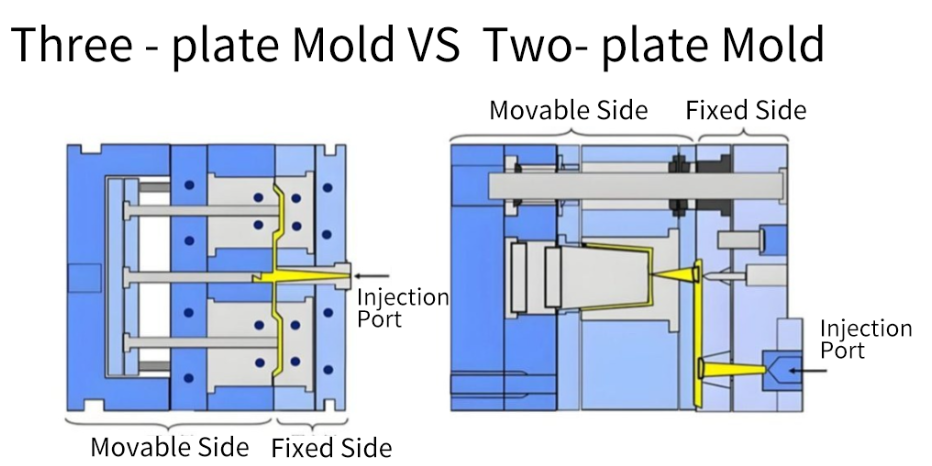

I. Structural Design Differences

Two-plate molds: Also known as large gate molds, they consist of two main components: the fixed mold and the moving mold. During operation, the moving mold directly separates from or closes with the fixed mold, enabling efficient movement. Gates are designed on the parting surface, with common types including edge gates and direct gates. The compact layout with fewer components results in lower manufacturing difficulty and costs, making them suitable for producing simple products.

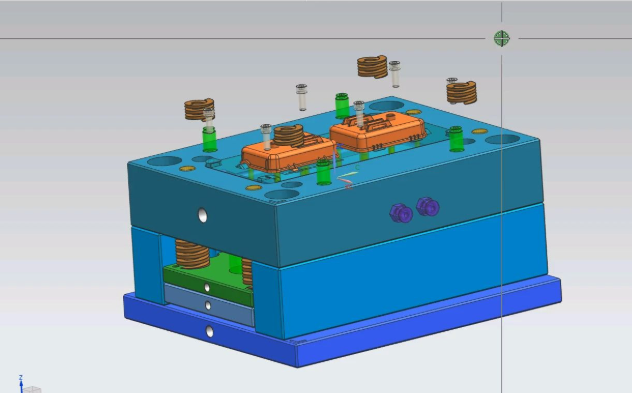

Three-plate molds: Composed of a fixed mold, a moving mold, and an intermediate runner plate, they feature two parting actions. The first parting occurs between the runner plate and fixed mold, while the second happens between the moving mold and fixed mold. They typically use pinpoint gates that reduce runner waste. However, the additional runner plate and stroke control devices (such as pull rods) increase structural complexity, precision requirements, and manufacturing costs, making them suitable for precision products.

II. Working Principle Differences

Two-plate molds: Molten plastic enters the cavity through the gate. After cooling, the moving mold separates from the fixed mold, and both the product and runner system are ejected together. Since the product and runner aren't automatically separated, subsequent processes are required to remove the gate, which may affect product appearance and increase costs.

Three-plate molds: During mold opening, the runner plate first separates from the fixed mold, breaking the pinpoint gate and initially separating the runner from the product. Then the moving mold separates from the fixed mold to eject the product. This design enables automatic gate separation from the product with minimal surface marks, improving appearance quality and reducing post-processing.

III. Application Scenarios

Two-plate molds: Suitable for products with simple structures and low requirements for dimensional accuracy and appearance, such as plastic hangers, trash cans, and general industrial components. Their low cost and high efficiency make them the preferred choice for small enterprises or small-batch production.

Three-plate molds: Used for products requiring high appearance quality, precision, and complex structures. Widely applied in electronics, automotive, and medical industries for items like phone casings and automotive interior parts. Their pinpoint gate design and automatic ejection meet high-precision requirements and offer environmental advantages by reducing waste.

IV. Cost-Effectiveness and Development Trends

Two-plate molds have lower manufacturing costs and shorter production cycles but generate more runner waste and incur higher post-processing costs, making them suitable for mass-produced simple products. Three-plate molds have higher manufacturing costs and energy consumption but offer better material utilization and reduced post-processing, making them suitable for high-end precision products.

In the new era, two-plate molds are being upgraded through intelligent technologies to improve efficiency and reduce waste. Three-plate molds are enhancing precision with 3D printing and integrating intelligent systems for full-process management. Enterprises should select mold types based on product characteristics, production scale, and cost budgets to meet the intelligent and green development needs of manufacturing.