Application examples of Precision injection Molding in 3C products

In the digital era, 3C products (computers, communications, and consumer electronics) have become integral to daily life. From smartphones to laptops and wearable devices, their development relies heavily on advanced manufacturing technologies. As a high-precision, efficient plastic molding process, precision injection molding plays a crucial role in 3C product manufacturing, widely used in producing housings, internal structural components, and electronic connectors.

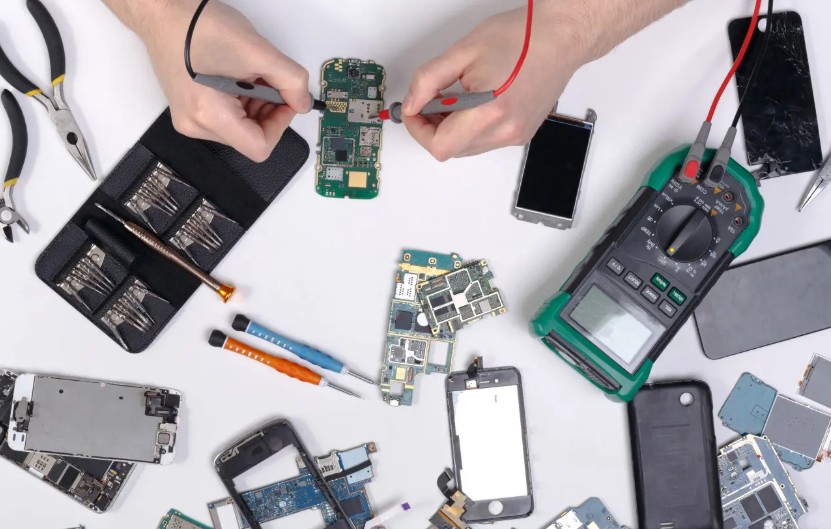

Applications in Smartphones

Housing Manufacturing

Lightweight through thin-wall design: Achieves 0.5-1mm wall thickness while maintaining structural strength, reducing overall device weight.

Enhanced aesthetic quality: Uses PC or PMMA materials with high-gloss injection molding to create mirror-like finishes, improving visual appeal.

High-precision fitting: Ensures accurate alignment of camera holes and button positions, facilitating subsequent assembly processes.

Internal Structural Components

Strict tolerance control: Maintains dimensional accuracy within ±0.05mm for motherboard brackets and similar parts.

Material performance optimization: Utilizes PA+glass fiber reinforced engineering plastics for reliable component support.

Lightweight layout support: Enables compact internal designs while ensuring structural integrity.

Buttons and Connectors

Reliable button performance: Ensures clear tactile feedback and durability through precision molding.

High-precision connectors: Achieves ±0.02mm dimensional accuracy for stable signal transmission.

Advanced sealing protection: Reaches IP67 or higher waterproof rating to protect internal circuits.

Applications in Tablets and Laptops

Product Housings

Material performance integration: Uses PC+ABS alloys combining strength and processability for impact resistance.

Aesthetic innovation: Implements IMD or two-color injection molding for personalized surface finishes.

Comprehensive performance balance: Meets aesthetic, protective, and heat dissipation requirements simultaneously.

Heat Dissipation Components

Optimized structural design: Creates complex-shaped plastic heat sinks to maximize cooling efficiency.

Enhanced thermal conductivity: Incorporates carbon fiber or graphite fillers to improve heat transfer.

Cost-effective advantages: Offers lighter weight and lower production costs compared to metal alternatives.

Keyboard and Touchpad Components

Precise keyboard control: Ensures uniform key spacing and consistent tactile feel through precision molding.

Functional material application: Adds wear-resistant and antibacterial additives to extend service life.

Smooth touch experience: Maintains dimensional accuracy for stable touchpad performance.

Applications in Other 3C Products

Camera Lens Components

Optical precision guarantee: Achieves micron-level accuracy for curvature and surface flatness using PMMA or COP materials.

Complex structure molding: Enables cost-effective production of aspherical lenses compared to glass alternatives.

Component stability support: Ensures overall lens stability and sealing through precision-molded housings.

Wearable Devices

Smartwatch manufacturing: Produces ultra-thin, lightweight cases with 5ATM+ waterproof performance.

Wireless earphone components: Creates precision-molded shells for acoustic performance and comfortable silicone ear tips.

Miniaturization support: Meets strict precision requirements for small, highly integrated devices.

Drones

Frame performance optimization: Produces lightweight, high-strength frames improving aerodynamic efficiency.

Propeller precision control: Ensures stable lift generation through accurately molded blade dimensions.

Internal protection assurance: Provides reliable electronic component protection in compact layouts.

In summary, precision injection molding enables high-precision, efficient production of complex structures across 3C products. It supports high-performance, miniaturized, lightweight, and personalized designs, driving continuous innovation in the electronics industry. As technology advances, precision injection molding will play an increasingly important role in 3C manufacturing.