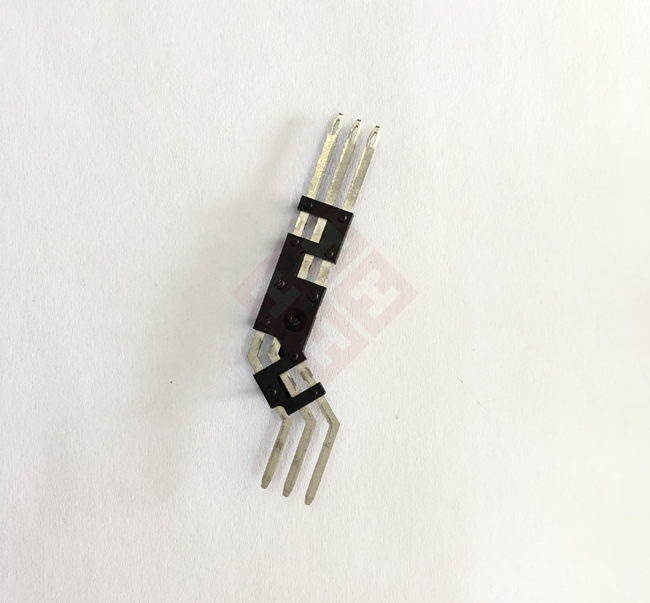

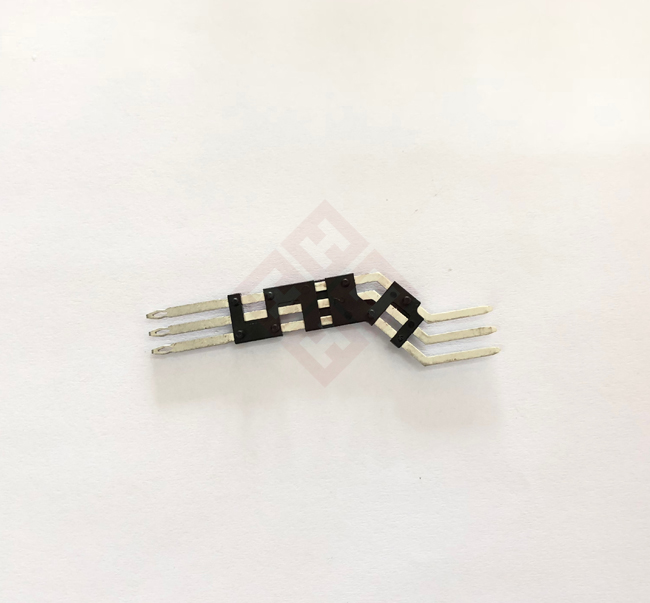

Metal - overmolding injection molds need to take into account both the positioning of metal inserts and plastic molding. Its core structure consists of two parts: the fixed mold and the moving mold. The fixed mold is responsible for cavity forming and melt injection, while the moving mold fixes the metal inserts and realizes the ejection function. The key design lies in the insert positioning system, which ensures accurate fixation of metal parts through slots, fixtures, or magnetic adsorption to prevent displacement during injection molding. The gate design should avoid the melt directly impacting the metal, and side gates or sub - gates are often used. Meanwhile, due to the high thermal conductivity of metal, the cooling system needs to be densely arranged around the cavity to shorten the molding cycle. In addition, the arrangement of venting grooves is essential to prevent problems such as air entrapment leading to bubbles or short shots.

H13 tool steel is mostly selected as the mold material and is nitrided to improve wear resistance. For corrosive plastics, S136 stainless steel is required. The bonding between metal and plastic relies on three methods: mechanical bonding increases the surface roughness of the metal through sandblasting and knurling, enabling the plastic to form an "anchoring" effect; chemical bonding uses coupling agents such as silane to form chemical bonds between the metal and the plastic; physical adsorption utilizes the wetting effect of the plastic melt on the metal surface to generate van der Waals forces for bonding. In practical applications, multiple methods are often combined according to the metal material and plastic type. For example, after anodizing aluminum alloy, a coupling agent is then coated, which greatly improves the peel strength of the overmolding layer.

Metal - overmolding injection molds are widely used in the automotive, electronics, and tool manufacturing industries. In the automotive industry, they are used for components such as steering column handles and shift knobs, combining the strength of metal with the anti - slip and shock - absorbing properties of plastic. In consumer electronics, notebook hinges and mobile phone brackets achieve wear resistance and insulation functions through overmolding. However, the industry faces many challenges: for example, the positioning accuracy of metal inserts is extremely high (the tolerance is often controlled within ±0.02mm), otherwise, the thickness of the overmolding layer is likely to be uneven; when the melt flows on the metal surface, it is prone to uneven cooling, resulting in weld lines or short - shot problems. Therefore, CAE simulation needs to be used to optimize the gate position and process parameters, and precision fixtures and intelligent temperature control systems should be adopted to ensure molding quality and production efficiency