As core components of industrial equipment sealing systems, oil seals are widely used in hydraulic transmission, rotating machinery, reciprocating mechanisms and other key parts, directly determining equipment operational stability and maintenance costs. Hydraulic oil seals, rotary shaft oil seals, piston rod oil seals, and reciprocating shaft oil seals have targeted structural designs, material selections and technical parameters due to different working principles and operating conditions. The following details are based on industry standards and practical application scenarios.

Mainly used for sealing fixed or moving parts in hydraulic systems to isolate hydraulic oil from the external environment, suitable for hydraulic pumps, motors, cylinders and other equipment. Structurally adopting a double-lip design with a dust-proof lip, they can work under medium-low to high pressure conditions, with a typical applicable pressure of 0-40MPa and special pressure-resistant types reaching 3MPa static pressure. Widely applied in construction machinery hydraulic circuits, industrial hydraulic stations and other scenarios.

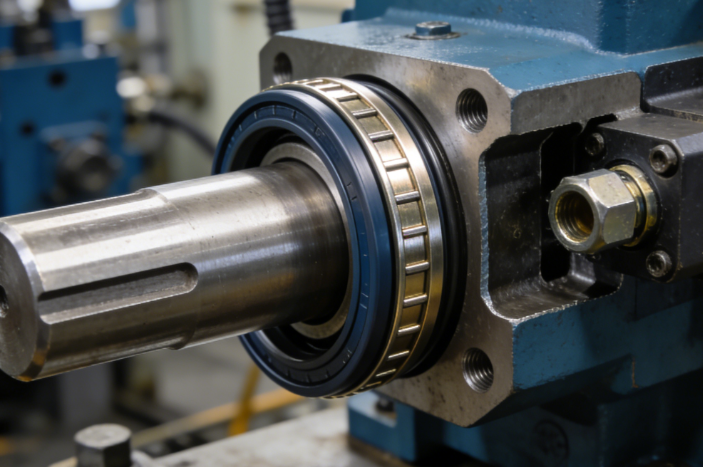

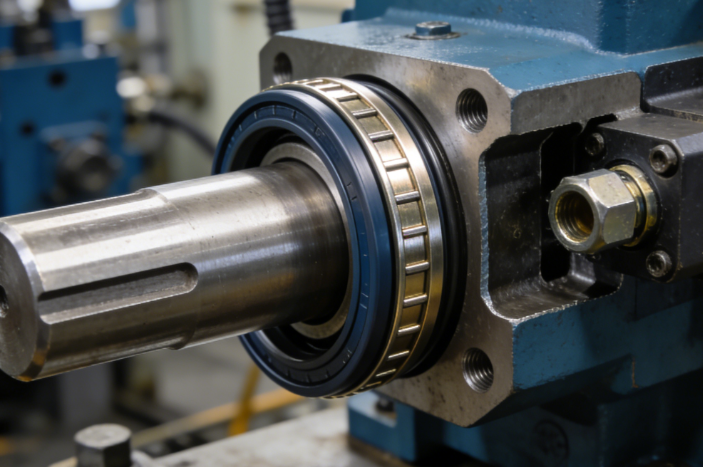

Designed for shaft rotational movement, their core function is to prevent lubricating oil leakage and impurity intrusion, suitable for motor shafts, gearbox shafts, pump shafts and other components. Classified into single-lip, double-lip and one-way return types by structure, the one-way return type achieves a return effect using fluid mechanics principles. The maximum linear speed can reach 20m/s, and the ordinary type has a linear speed ≤15m/s, applicable to machine tool spindles, automobile gearboxes and other rotating equipment.

Adapted to the reciprocating movement of hydraulic cylinder piston rods, they need to balance wear resistance and extrusion resistance, commonly used in hydraulic cylinders, construction machinery oil cylinders and other parts. Made of polyurethane or modified rubber materials, their wear resistance is 3-5 times that of ordinary nitrile rubber, with a working pressure of up to 25MPa, capable of resisting friction loss during high-frequency reciprocating movement. Suitable for heavy-load scenarios such as mining machinery and automated production lines.

Designed for reciprocating shaft components such as hydraulic valve stems and cylinder piston rods, requiring excellent elastic recovery and sealing stability. The operating temperature range is -60℃~180℃, and the reciprocating speed is ≤0.1m/s. Dynamic sealing is achieved through lip compression control (5%-10%), applicable to low-pressure reciprocating hydraulic systems, pneumatic actuators and other equipment.

Temperature adaptation: -20℃~120℃ for conventional working conditions; fluororubber materials can reach 250℃ for extreme high-temperature scenarios, and silicone materials can withstand as low as -60℃ for low-temperature scenarios;

Pressure range: 0-40MPa for hydraulic oil seals, ≤25MPa for piston rod oil seals, ≤0.05MPa static pressure for rotary shaft oil seals (excluding pressure-resistant types);

Movement speed: ≤20m/s for rotary shaft oil seals, ≤0.1m/s for reciprocating shaft oil seals, ≤0.5m/s for piston rod oil seals;

Lip parameters: Shore hardness 70-85A, compression rate controlled at 5%-10% to ensure uniform sealing contact pressure.

Must comply with GB/T 13871 standard for rotary shaft lip seals. Products for high-temperature working conditions shall pass the 200℃×500h accelerated aging test with a hardness change not exceeding ±10%; dimensional accuracy error shall be controlled within ±0.01mm to meet the sealing requirements of precision equipment.

Nitrile Rubber (NBR): Oil-resistant and temperature-resistant (-30℃~100℃), suitable for medium-low pressure and normal temperature oil medium scenarios such as ordinary hydraulic systems and gearbox seals;

Fluororubber (FKM): Temperature-resistant (-20℃~200℃), resistant to acids, alkalis and synthetic oils, suitable for high-temperature and strong corrosion working conditions such as chemical equipment and aviation hydraulic systems;

Silicone Rubber (VMQ): Wide temperature range (-60℃~180℃), non-toxic and odorless, suitable for food machinery and new energy vehicle battery pack seals;

Polyurethane (PU): Wear-resistant and extrusion-resistant, temperature-resistant (-20℃~120℃), preferred for reciprocating components such as piston rods and reciprocating shafts.

Performance improvement through carbon fiber reinforcement, nano-filling and other technologies. For example, 25% carbon fiber-reinforced fluororubber retains 68% of its tensile strength after aging at 250℃ for 1000 hours; carbon nanotube-modified materials can reduce wear volume by 40%, meeting the requirements of extreme working conditions.

Clean the seal groove and shaft surface to remove iron filings and oil stains, avoiding scratches on the seal lip;

Use special installation tools, prohibit excessive stretching or twisting of the seal ring, and apply suitable lubricants to the lip (mineral oil for rubber, silicone-based lubricants for silicone);

Control the installation interference to ensure tight fit between the seal lip and the shaft surface without bubbles or gaps.

Maintenance cycle: 6-12 months for conventional working conditions, 3-6 months for extreme working conditions; regularly inspect seal surface wear and leakage;

Failure forms: Leakage, lip hardening and cracking, excessive wear, mostly caused by improper material selection, installation damage or exceeding working condition limits;

Treatment measures: Replace with appropriately sized material seals, optimize installation processes, and add retaining rings to prevent extrusion if necessary.

Wider application of high-performance composite materials, such as fluororubber-silicone blends balancing wide temperature range and chemical resistance, and hydrogenated nitrile rubber with over 30% performance improvement; gradient structure design increases the uniformity of sealing contact pressure by 45%.

Embedded sensors realize real-time monitoring of sealing status with a fault prediction accuracy of 92%; development of halogen-free flame-retardant and low-VOC materials accelerates to meet the cleanliness requirements of new energy and semiconductor industries.

For high-temperature (>250℃) and high-pressure (>30MPa) scenarios, metal skeleton-reinforced seals are developed with extrusion resistance up to 45MPa; diamond-like carbon coating on the surface controls the friction coefficient below 0.1, reducing heat generation.