Technical Guide to Composite Material Specimen Test Molds and Metal Powder Specimen Test Molds Hoorenmold

In material performance testing, key indicators of composites and metal powders require precise evaluation via standard spline testing. Composite material spline testing molds and metal powder spline testing molds are core equipment for this process, demanding material-specific designs to address composite fiber distribution/curing shrinkage and metal powder fluidity/compression rebound. Their structural rationality, manufacturing precision, and operational standardization directly determine test sample quality consistency and the reliability of performance results. Acting as a "bridge" between material preparation and performance evaluation, these molds support tensile/bending property verification in composite R&D and compressive strength detection in metal powder production, providing critical technical backing for high-performance material R&D and mass production in new energy, aerospace, and other sectors.

1. Key Design Adaptations

1.1 Composite Material Specimen Test Molds

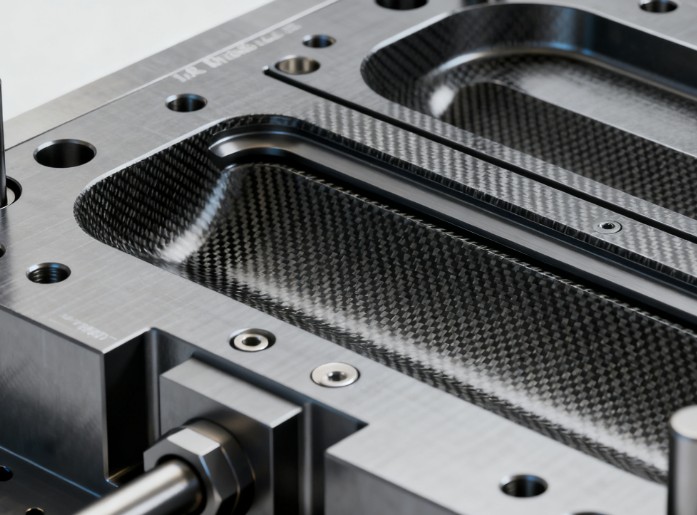

To address issues like uneven fiber distribution and curing shrinkage in composites, mold design focuses on: conforming to ASTM standards (e.g., tensile and flexural test specifications), achieving a low surface roughness to prevent fiber damage, reserving shrinkage compensation based on thermosetting resin properties (e.g., epoxy resin), adopting fan-shaped or film-style runners for uniform fiber distribution, and integrating multi-stage heating modules for precise temperature control during gradient curing to avoid material degradation from local overheating.

1.2 Metal Powder Specimen Test Molds

For stable metal powder molding, molds feature: modular frames with tightly controlled punch-die clearances to prevent powder leakage, adjustable compression strokes for varying density requirements, combined ejector tube and push rod ejection systems with optimized draft angles to reduce cracking, hardened inner surfaces for ultra-fine powder molds to minimize adhesion, and side vents to eliminate air pockets during compression.

2. Manufacturing Processes & Material Selection

2.1 Manufacturing Processes

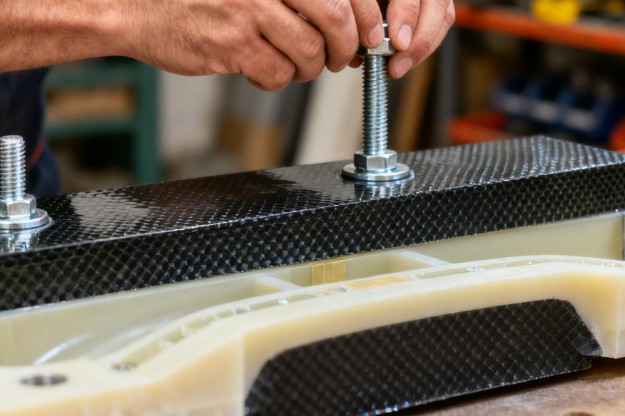

Composite Molds: 5-axis CNC milling for cavities, followed by EDM finishing for critical surfaces to ensure dimensional accuracy. Precision dowel pins are used for assembly, with PP-based composite test runs to adjust gate dimensions for optimal filling.

Metal Powder Molds: Wire EDM for punches and dies (slow-feeding wire EDM for complex cavities to reduce deformation), precision polishing of molding surfaces, and wear-resistant coating application to extend service life for high-volume production.

2.2 Material Selection

Composite Molds: Pre-hardened steel for standard temperature applications, hot work tool steel for high-temperature scenarios, and carbon structural steel for mold bases to balance strength and cost-effectiveness.

Metal Powder Molds: Tungsten carbide for high-wear molding components, cold work tool steel for small-to-medium batch production, and bearing steel for guide components to maintain precision.

3. Application & Operational Procedures

3.1 Composite Mold Applications

Used for producing test specimens (e.g., carbon fiber/epoxy composites) complying with national standards. Operational steps include: preheating and insulating the mold, cutting and laying prepreg to avoid fiber wrinkling, applying pressure via hydraulic press with dwell time for full curing, and demolding at reduced temperatures to prevent thermal cracking.

3.2 Metal Powder Mold Applications

Used for manufacturing metal powder specimens (e.g., 316L stainless steel) meeting national compression strength standards. Procedures involve: vacuum-drying powder to remove moisture, precision feeding for consistent batch weights, cold compaction with controlled speed and dwell time to minimize springback, and careful handling of green compacts prior to sintering and testing.

4. Quality Control & Maintenance

4.1 Composite Molds

Regular inspections of cavity dimensions and surface roughness with professional equipment; rework or polishing as needed. Monitor specimen defect rates during test runs and adjust parameters accordingly. Clean cavities with alcohol post-use, lubricate guide mechanisms periodically, replace heating elements per service life, and promptly tighten or replace loose dowel pins.

4.2 Metal Powder Molds

Periodic hardness testing of punches and dies (reheat treat if hardness drops excessively), annual ultrasonic flaw detection for internal cracks, and gap inspection with lapping as required. Remove residual powder with compressed air after use, reapply coating when worn, and store with rust inhibitor in a dry environment for long-term preservation.

5. Technological Innovation & Core Value

5.1 Technological Trends

Intelligent Upgrades: Integrate temperature/pressure sensors for real-time monitoring, leverage AI algorithms to optimize processes and improve specimen qualification rates, and implement vibration monitoring for predictive maintenance.

Green Development: Promote recycled mold steel and eco-friendly rust inhibitors, develop low-temperature curing molds to reduce energy consumption, and adopt laser cladding for mold repair to extend service life and minimize waste.

5.2 Core Value

As critical equipment for material performance testing, these molds require precise material-specific design and manufacturing. Future technological advancements will enhance their support for high-performance material R&D and mass production in new energy, aerospace, and other key sectors, ensuring reliable quality control and innovation.