How to Ensure the Specification Precision of Custom Plastic Parts

In custom plastic part manufacturing, specification precision directly determines product performance and compatibility. Precision control must run through the entire process of mold design, material handling, molding process, and quality inspection, achieving accurate control through multi-link coordination.

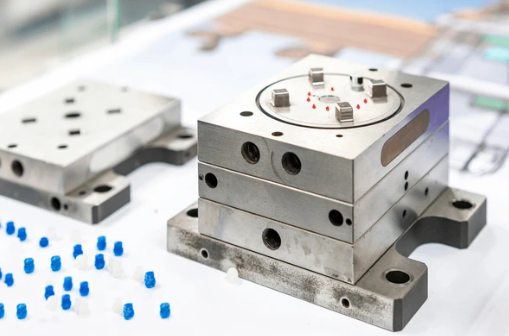

1. Mold Design & Manufacturing: The Foundation of Precision

(1) Precise Planning in Design Phase

Shrinkage Compensation: Adjust mold dimensions in advance based on material shrinkage and mold flow analysis to avoid dimensional deviations.

Gate & Runner Optimization: Choose appropriate gate types (e.g., multi-point gates for large parts) and design short, smooth runners to ensure uniform melt filling.

Cooling System Matching: Layout cooling channels by product thickness; use conformal cooling for thick-walled areas to control mold temperature difference.

(2) Precision Control in Manufacturing

High-Precision Processing: Adopt wire EDM, precision grinding, and 5-axis machining to ensure mold cavity/core accuracy.

Key Dimension Monitoring: Use CMM to inspect critical dimensions and establish a processing parameter traceability system.

2. Material Selection & Handling: The Premise of Stability

(1) Prioritize Stable Materials

Precision-Based Selection: Choose engineering plastics for high-precision products due to their stable shrinkage.

Batch Consistency Control: Verify melt flow rate and shrinkage via supplier reports and sampling.

(2) Strict Pretreatment

Drying: Dehumidify hygroscopic materials to prevent defects like silver streaks.

Impurity Removal: Use sieves, magnetic separators, and filters to ensure material purity.

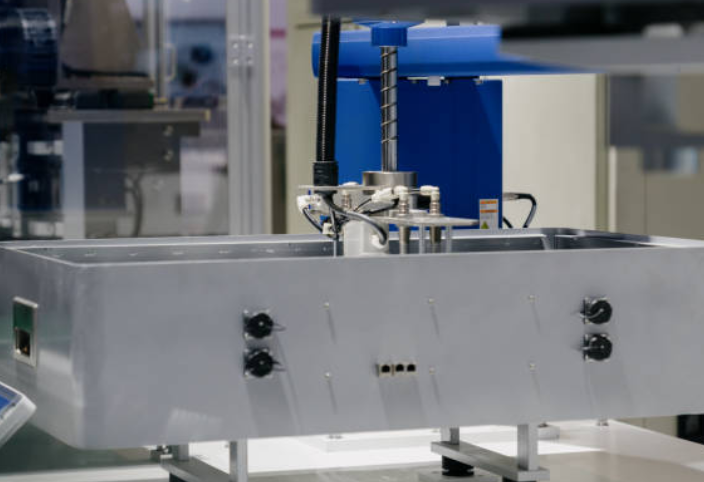

3. Molding Process Regulation: The Core of Precision

(1) Accurate Temperature Control

Barrel Temperature: Match settings to material properties; maintain stability with precision controllers.

Mold Temperature: Lower for thin-walled parts (shorter cycle) and keep high/uniform for complex parts.

(2) Pressure & Speed Optimization

Injection Pressure: Adjust based on product structure; monitor cavity pressure dynamically.

Hold Pressure & Injection Speed: Set hold pressure at 60%-80% of injection pressure; use high speed for thin parts, low speed for thick parts.

(3) Cooling Time Control

Optimize based on material thermal performance and product thickness to ensure full curing before demolding.

4. Quality Inspection & Monitoring: The Final Check

First Article Inspection: Conduct full-dimension testing before mass production.

In-Process Sampling: Use SPC to monitor dimensions; stop production for anomaly investigation.

Finished Product Verification: Use laser scanning to compare 3D data with CAD models for process improvement.

Comprehensive precision control across the entire process ensures the specification accuracy of custom plastic parts, meeting industry demands for compatibility and reliability.