Plastic Mold Manufacturing: Standard Processes and Core Technical Points

Plastic mold manufacturing is a core prerequisite for mass production of plastic products. The standardization of its processes and precise control of technical parameters directly determine mold service life, molding efficiency, and product quality stability. Below is a professional analysis from two aspects: manufacturing processes and core technologies.

1. Standard Implementation of Manufacturing Processes

1.1 Demand Analysis and Material Matching

Based on 3D models and 2D engineering drawings provided by customers, conduct product structure feasibility analysis, focusing on undercut structures, thin-walled areas (reinforcement ribs needed for excessive thinness), and deep cavity structures (ejection mechanism optimization required for large depth-diameter ratios). Match raw materials to product performance needs: PMMA or PC for optical-grade products, ASA for weather-resistant parts, and ABS/PC alloy for structural load-bearing components.

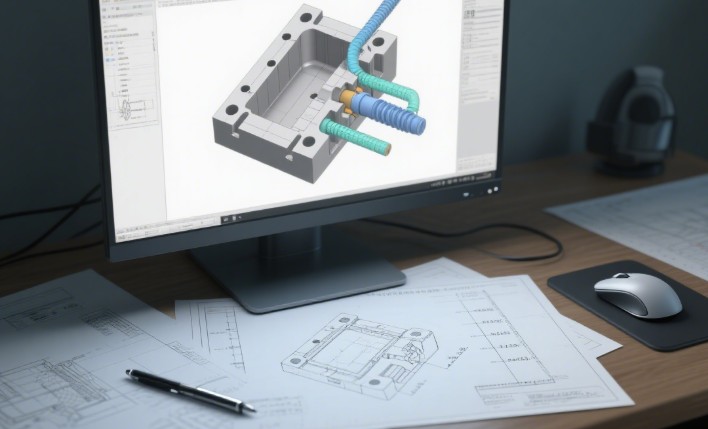

1.2 Digital Design and CAE Verification

Complete mold structure design using UG NX or SolidWorks. Parting surface design must meet the "maximum contour principle" and "ejection smoothness". Sprue and runner adopt gradient size design. Use Moldflow to simulate filling, packing, and cooling processes, optimize gate quantity and position to reduce weld lines, shrinkage marks, and other defects. Rational application of CAE can significantly reduce test molding times.

1.3 Mold Steel Selection and Quality Inspection

Determine mold steel grades by production volume: high-quality pre-hardened steel such as 718H and NAK80 for mass production; economical steel like S50C for prototypes or simple molds. Test raw material hardness with a hardness tester and observe grain structure via metallographic analyzer. Conduct ultrasonic testing on key molding parts to eliminate inclusions and cracks.

1.4 Precision Machining and Surface Strengthening

Use CNC vertical machining centers for roughing, leaving appropriate finishing allowances. Achieve high surface finish on molding surfaces via high-speed milling. Process complex cavities with EDM, strictly controlling electrode wear. Improve surface hardness and wear resistance significantly through gas nitriding after machining.

1.5 Assembly, Debugging and Acceptance Delivery

Adopt precision transition fit for guide pillars and bushes to ensure smooth opening/closing and accurate positioning. Set process parameters based on material properties during test molding. After multiple process optimizations, conduct full-size inspection in accordance with GB/T 14486-2021 Plastic Mold Technical Conditions and appearance acceptance per ASTM D4060 standard.

2. Core Technical Parameter Control

2.1 Gating System Design

Set reasonable sprue taper, with inlet diameter matching injection machine nozzle. Prioritize circular cross-section for runners to reduce melt flow resistance. Use pin gates for appearance parts and edge gates for structural parts, selecting appropriate gate type and size based on product characteristics.

2.2 Cooling System Optimization

Arrange cooling channels close to the cavity for uniform cooling and to prevent product deformation. Determine channel diameter and spacing based on product shape, wall thickness, and plastic thermal properties. Use 3D-printed conformal channels for irregular parts to significantly improve cooling efficiency and shorten molding cycle.

2.3 Precision Control System

Implement first article inspection with a coordinate measuring machine during machining. Calibrate parallelism and perpendicularity with a dial indicator during assembly. Cover dimensional tolerance, geometric tolerance, and surface roughness in final acceptance to ensure mold precision meets design requirements.