How is the cost of opening a plastic mold calculated

In plastic mold partnerships, the rationality of tooling costs is a core decision-making factor for customers. However, costs

are not isolated figures—they are systematic outcomes deeply tied to product features, technical standards, and production

scale. Leveraging over 20 years of precision mold expertise, we analyze the key variables shaping tooling costs and how

technical adaptation achieves "quality compliance + cost control."

1. Why Costs Vary: Requirements Drive Configuration

The cost gap between seemingly similar molds often stems from three core dimensions:

Product Structure Defines Baseline Costs

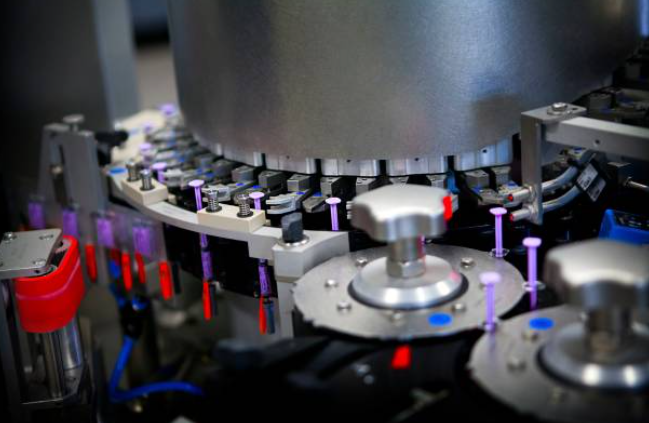

Complexity: Molds for deep cavities, undercuts, or irregular shapes (e.g., EV battery cases, medical connectors) need lifters or

core pulls, with tolerances as tight as ±0.01mm—driving higher costs than simple flat molds.

Material Compatibility: For high-temperature (PEEK) or corrosive (PVC) materials, special steels (H13, S136) and treatments

(nitriding, chrome plating) ensure 500,000+ cycle durability, increasing material costs.

Batch Size: Small runs (1,000–5,000 units) use 3D-printed rapid molds (70% faster delivery); large-scale production (100,000+ units)

requires steel molds for stability, with higher upfront costs but lower unit amortization.

Industry Standards Elevate Technical Rigor

Regulatory demands directly impact costs:

Medical Molds: ISO 13485 certification requires Class 8 cleanrooms and biocompatibility checks.

Automotive Molds: IATF 16949 mandates vibration/temperature testing, with mold flow analysis requiring multiple simulations.

Food-Grade Molds: FDA compliance demands Ra 0.02μm polishing to prevent microbial contamination.

2. Technology Breaks the "Quality vs. Cost" Tradeoff

Smart, sustainable technologies redefine cost-efficiency:

Intelligent Design Cuts Trial-and-Error Waste

AI Mold Flow Analysis (integrating Moldflow + proprietary algorithms) predicts weld lines/sink marks, reducing trial runs from 3–4

to 1–2, slashing trial costs by 50%.

Modular Design standardizes guide pillars/ejector pins, trimming complex mold development time by 40% and simplifying maintenance.

Hybrid Manufacturing Optimizes Spending

For complex cooling channels/geometries, "3D Printing + CNC" cuts cooling time by 60% at a 15% cost premium (vs. full 3D printing).

Recycled Steel (90% as strong as virgin steel) combined with laser cladding extends mold life by 30% and cuts material costs by 20%.

3. Professional Services: Tailored to Your Needs

We avoid "one-size-fits-all" quoting. Instead, we deliver end-to-end support:

From design-phase feasibility checks (structural optimization, material matching) to mass production quality assurance and

post-delivery maintenance, we balance cost and efficiency. Share your product drawings, material specs, and production

goals—we’ll provide customized tooling recommendations promptly.