Analysis and Solutions to Mold Opening Failures

In mold manufacturing and injection molding, mold opening connects design to finished products. Despite advancing mold technology, opening failures still disrupt production and quality. This article analyzes common issues and solutions.

1. Mold Sticking: Design and Maintenance Issues

(1) Root Causes

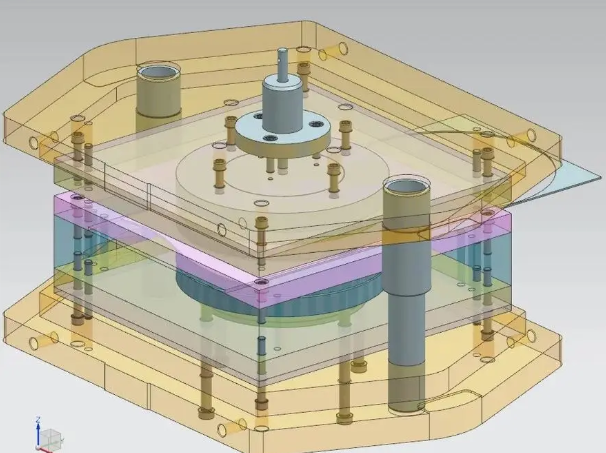

Design Flaws: Poorly designed guiding mechanism clearances or unbalanced stripping mechanisms cause component interference, especially in multi-parting surface and side core-pulling molds with improper movement sequences.

Inaccurate Force Control: Mismatched injection machine opening force—insufficient force fails to overcome resistance; excessive force deforms fragile parts, creating sticking "deadlocks."

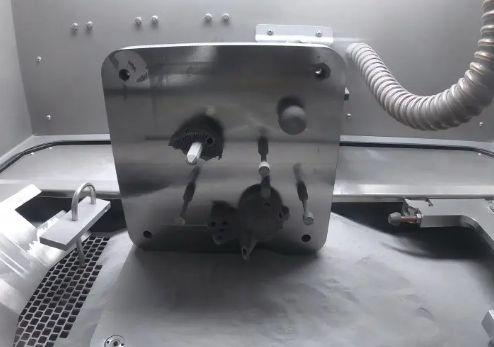

Cumulative Wear: Long-term high-frequency production causes surface peeling and dimensional deviations in cavities and sliders. High temperatures accelerate wear, worsening component fits.

Environmental Contamination: Dust, debris, and scraps enter through parting surfaces/vents, jamming moving parts during opening.

(2) Countermeasures

Design Optimization: Use CAE to simulate opening; add pre-stripping mechanisms for complex molds. Optimize part thickness via mold flow analysis.

Equipment Adaptation: Dynamically adjust opening force/speed based on mold properties. Use pressure-displacement monitoring to trigger "soft opening" during force fluctuations.

Full-Cycle Maintenance: Inspect with coordinate measuring machines; repair worn parts via laser cladding. Replace seals/guide bushings regularly.

Environmental Control: Deploy dust suction devices; store idle molds in climate-controlled cabinets.

2. Part Damage: Process and Mold Coordination Failures

(1) Damage Causes

Opening Force Impact: Excessive force cracks thin/high-precision parts. Uneven hot runner gate temperatures cause local overload and defects.

Positioning Failure: Deformed locating components reduce clamping accuracy, leading to part position deviations and stripping interference.

Uneven Cooling: Poor cooling circuit design causes uneven shrinkage and internal stress, with cracks forming at stress points (e.g., wall transitions).

(2) Solutions

Precise Force Control: Use two-stage opening for thin parts. Maintain hot runner temperature differences within ±2℃.

Reconstruct Positioning: Replace worn components; adopt "mechanical + photoelectric" positioning. Compensate errors via laser interferometry.

Cooling Upgrade: Optimize circuits with CFD; add spiral channels in thick areas. Use sensors to adjust cooling water flow.

3. Stripping Resistance: Material-Mold Interactions

(1) Resistance Causes

Inappropriate Draft Angles: Poorly designed angles for material shrinkage, especially insufficient angles at undercuts/blind holes, increase resistance—worse with low-shrinkage glass fiber-reinforced plastics.

Surface Deterioration: Inadequate cavity polishing (roughness > Ra0.8μm), oxidation, and residue buildup increase sticking. Glass fibers scratch cavities, worsening issues.

Shrinkage Fluctuations: Process parameter variations cause >5% shrinkage deviations, making parts clamp tightly to cores.

(2) Solutions

Scientific Draft Design: Use material PVT curves for differentiated angles (≥1.5° for deep areas; ≥0.5° for appearance). Optimize gates via mold flow analysis.

Surface Treatment: Apply diamond polishing + nano-coatings to achieve <Ra0.2μm roughness. Use TiN coatings for glass fiber-reinforced plastics.

Process Compensation: Embed shrinkage-parameter models; adjust holding time/cooling. Add gas-assisted stripping for difficult parts.

Solving opening failures requires design, process, and maintenance collaboration. CAE simulation, intelligent control, and proactive maintenance ensure efficient opening, supporting manufacturing quality and cost goals.