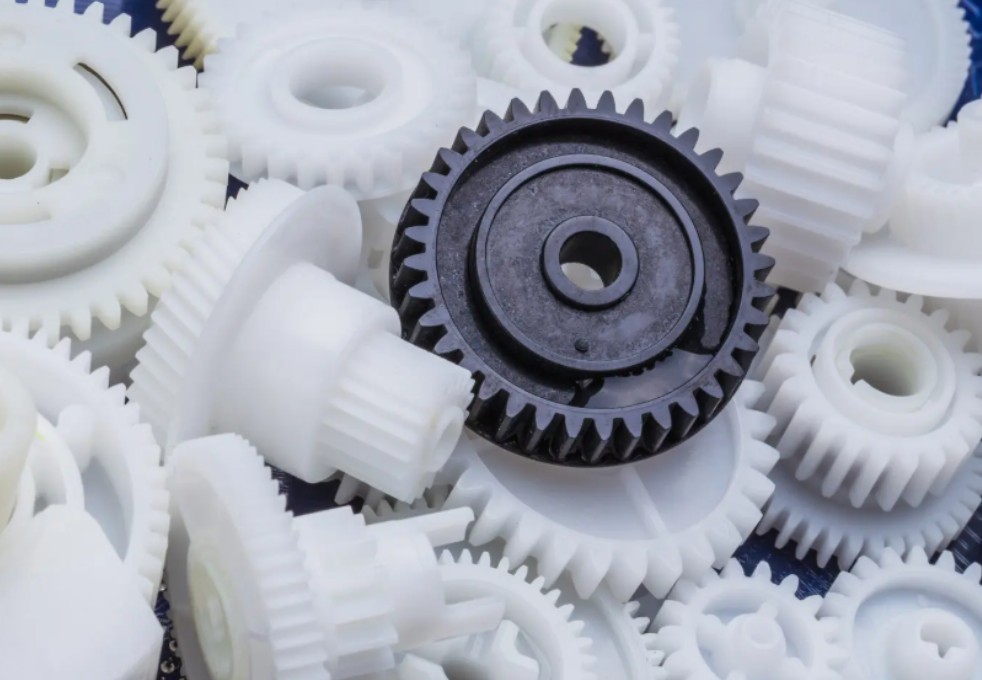

Technical Essentials of Precision Injection Molding for Polyoxymethylene (POM)

Polyoxymethylene (POM) has become indispensable in precision injection molding due to its excellent mechanical

properties and dimensional stability, widely used in electronics, automotive, and medical sectors. Mastering its core

technical essentials ensures product accuracy and reliability.

Material Pretreatment: Preventing Molding Issues

Though POM has low hygroscopicity (equilibrium water absorption ~0.22%), surface moisture causes degradation at

high temperatures, leading to bubbles or silver streaks. It requires hot-air drying at 80-90°C for 2-3 hours to reduce

moisture below 0.05%. Dried material must be conveyed through sealed systems to avoid reabsorption. Barrel temperature

control is critical—maintain rear sections 10-15°C cooler than front sections to prevent premature melting and uneven

plasticization.

Mold Design: Precision Foundation

Mold design must account for POM’s 1.8%-2.5% shrinkage, using mold flow analysis to set accurate compensation coefficients.

Segmented shrinkage rates (2.2% for thick sections, 1.9% for thin areas) ensure precision. Conformal cooling channels maintain

cavity temperature differences ≤5°C; thick sections need additional cooling wells with 3-5 second extended cooling times. Draft

angles should be ≥0.5° with surface roughness Ra ≤0.4μm. Deep-cavity parts require combined ejection mechanisms (ejector

pins + stripper plates) for uniform force distribution and deformation prevention.

Injection Parameter Optimization

Barrel temperatures should stay between 190-220°C, with nozzles 5-10°C cooler. Melt temperatures exceeding 230°C cause

degradation, requiring infrared monitoring. Injection pressures range 100-150 MPa, using multi-stage speed control (60% initial

speed, 30% near cavity fill) to reduce shear stress. Holding pressure at 60%-80% of injection pressure, with holding time adjusted

to wall thickness (1-2 seconds/mm). Cooling occupies 50%-60% of the cycle, ensuring ejection temperature below 110°C. Mold

temperatures maintained at 80-100°C via controllers enhance crystallinity and stability.

Post-Processing and Quality Control

High-precision parts need annealing at 120°C for 2 hours with slow cooling, eliminating over 80% internal stress. Coordinate

measuring machines inspect critical dimensions with ±0.002mm accuracy. For mass production, hourly 5-sample inspections

and X-R control charts ensure Cpk ≥1.33. Tensile tests verify strength ≥60MPa, while friction testers maintain coefficients at 0.15-0.25.

Common defects require targeted solutions: warping needs cooling optimization and annealing; sink marks demand increased

holding pressure and cooling time; silver streaks require better drying and lower melt temperatures; flash necessitates higher

clamping force or mold repairs.

By integrating precise material handling, mold design, parameter control, and quality checks, POM precision injection molding

meets the stringent requirements of 5G communications, new energy vehicles, and other high-end manufacturing fields, ensuring

reliable performance of precision components.