How Precision Injection Molding Optimizes New Energy Vehicle Battery Systems

1. Enhancing Structural Safety of Battery Packs

Precision injection molding provides reliable structural solutions for battery packs. Using high-strength engineering plastics like PEEK and PA66 GF, it produces battery case components with dimensional tolerances controlled within ±0.02mm. These components feature uniform wall thickness (2-3mm typical) and excellent impact resistance, effectively resisting external collisions and vibrations.

The integrated molding process eliminates assembly gaps, enhancing the battery pack's waterproof and dustproof performance to IP67 standards. Precision-machined cooling channel structures ensure even spacing between battery cells, preventing thermal runaway risks caused by uneven heat distribution.

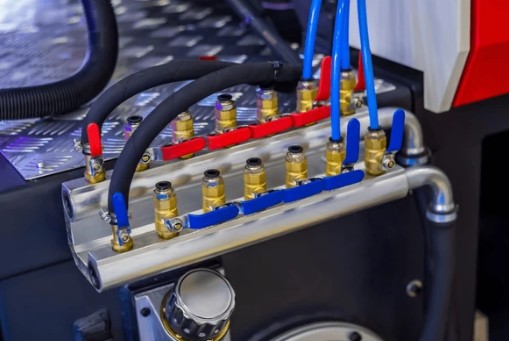

2. Improving Thermal Management Efficiency

Precision injection molding enables complex cooling system designs. Micro-channel heat sinks with 0.5-1mm diameter flow paths can be accurately formed, increasing heat exchange area by over 30% compared to traditional structures.

Thermally conductive plastic components, blended with graphene or aluminum nitride fillers, achieve thermal conductivity of 2-5 W/(m·K), efficiently transferring heat from battery cells to cooling systems. The tight fit between injection-molded thermal pads and cell surfaces reduces thermal resistance to less than 0.1℃·in2/W, ensuring consistent operating temperatures across all cells.

3. Reducing Weight and Increasing Range

By replacing metal parts with high-performance injection-molded plastics, battery system weight is reduced by 20-30%. For example, PA66 GF30 battery brackets weigh 40% less than aluminum alloy equivalents while maintaining comparable strength.

The lightweight design directly improves vehicle energy efficiency, increasing driving range by 5-8% per 10kg weight reduction. Precision molding of thin-walled structures (minimum wall thickness 1.2mm) further reduces material usage without compromising structural integrity.

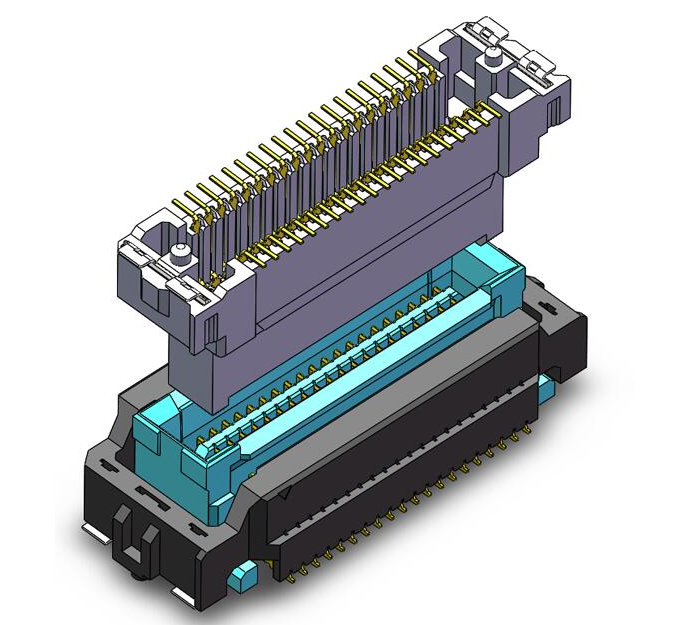

4. Enhancing Electrical Safety Performance

Injection-molded insulating components, made from materials with volume resistivity exceeding 101? Ω·cm, provide reliable electrical isolation between battery cells and external circuits. Precision-machined busbar housings ensure creepage distances and clearances meet IEC 60664 standards.

Flame-retardant plastic grades (UL94 V0 rating) prevent fire spread in abnormal conditions. The high dimensional accuracy of injection-molded parts ensures stable contact pressure in electrical connections, reducing contact resistance and overheating risks.

5. Enabling Integrated and Intelligent Design

Precision injection molding supports multi-functional integration, combining structural support, thermal management, and electrical insulation in single components. This reduces part counts by 30-40% and assembly time by 25%.

Incorporation of sensor mounting features during molding enables real-time temperature and voltage monitoring within the battery system. The design flexibility of injection molding facilitates rapid iteration of battery pack structures to adapt to different vehicle models and energy density requirements.

6. Supporting Mass Production and Cost Control

High-precision molds (with service lives exceeding 1 million shots) ensure consistent part quality during mass production. Automated production processes achieve Cpk values above 1.33, meeting strict automotive quality standards.

Injection molding reduces post-processing requirements, lowering manufacturing costs by 15-20% compared to traditional machining. Material utilization rates exceed 90%, minimizing waste and supporting sustainable production practices in the new energy vehicle industry.