The Application of PEEK Engineering Plastics in Precision Injection Molding

Introduction

In the era of advanced manufacturing, precision injection molding demands superior materials. PEEK (Polyether Ether Ketone), a benchmark special engineering plastic, has become pivotal in precision injection molding due to its exceptional properties. It drives technological upgrades in electronics, automotive, and medical sectors, supporting high-end manufacturing development.

I. Core Performance Advantages of PEEK

PEEK offers outstanding properties for precision molding: tensile strength exceeding 100MPa with excellent rigidity and fatigue resistance; long-term service temperature up to 260°C with stable high-temperature performance; strong resistance to acids, alkalis, and solvents; and low friction coefficient providing good self-lubrication and wear resistance, extending product lifespan.

II. Key Application Scenarios

(1) Electronics and Information

In 5G devices, PEEK precision-molded connectors ensure stable high-frequency signal transmission with excellent insulation and heat resistance. For chip packaging, PEEK's ultra-thin structures adapt to miniaturization trends while protecting chips from temperature fluctuations.

(2) Automotive Industry

PEEK components like intake manifolds and water pump impellers withstand engine heat, pressure, and vibration, reducing weight and improving fuel efficiency. In new energy vehicles, PEEK sensor housings and ECU shells provide reliable electrical insulation and electromagnetic shielding for intelligent systems.

(3) Medical and Health

PEEK's biocompatibility makes it ideal for implantable devices (artificial joints, spinal implants), reducing rejection and enhancing surgical outcomes. Medical equipment accessories made from PEEK maintain stability after repeated high-temperature sterilization.

III. Core Process Points

(1) Material Pretreatment

Critical drying at 150-200°C reduces moisture below 0.02% to prevent defects. Reinforced PEEK composites require uniform mixing via twin-screw extruders for consistent performance.

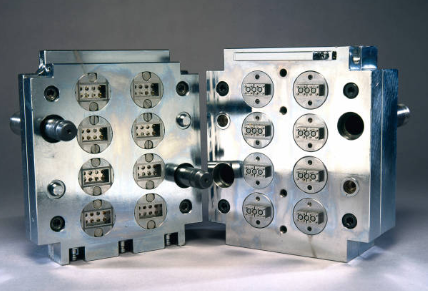

(2) Mold Design Standards

Molds require ±0.01mm dimensional tolerance with shrinkage compensation for PEEK's characteristics. High-temperature resistant hot work die steel with nitriding treatment ensures durability and surface precision.

(3) Injection Process Control

Precise temperature control (380-420°C) for barrel, nozzle, and mold. Optimized pressure/speed parameters ensure full cavity filling while preventing flash. Scientific cooling systems with controlled timing avoid deformation and internal stress.

IV. Development Trends and Challenges

(1) Main Trends

Intelligent production uses sensors and AI for real-time process optimization and fault. Functional modification adds conductivity, antibacterial, and self-healing properties. Green manufacturing focuses on waste reduction and recycling technologies.

(2) Key Challenges

High production costs limit large-scale application. Technical hurdles include high-temperature fluidity control and dimensional accuracy assurance. A shortage of professionals skilled in both PEEK properties and precision molding restricts innovation.