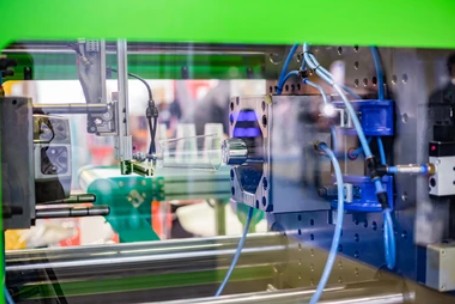

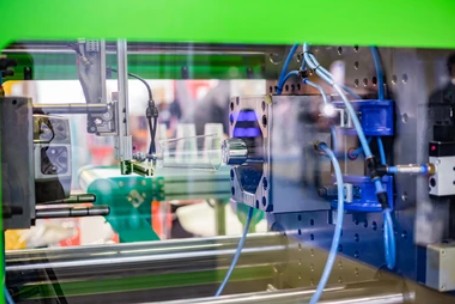

I. Concept of Precision Injection Molding

Precision injection molding is a high-precision injection production process that can limit the dimensional error of plastic products within 0.01 mm, generally in the range of 0.01 to 0.001 mm.

In the current environment where the manufacturing industry is developing towards miniaturization and high precision, its importance far exceeds that of ordinary injection molding, with more stringent requirements on equipment, molds and production processes.

This technology has two core measurement standards.

Equipment precision: The weight repeat error of ordinary injection molding machines is about 1%. When the error is less than 0.5%, it is called a precision machine; when less than 0.3%, it is an ultra-precision machine. The current international top level has reached below 0.15%, and the precision of key parameters such as injection position and pre-plasticizing position must be less than 0.03 mm.

Mold precision: It needs to be guaranteed by high-precision processing equipment and is an indispensable basic condition for realizing precision injection molding.

II. Classification of Precision Injection Molding

From the perspective of molding processes, there are several different types.

Standard precision injection molding: This method completes production by precisely controlling parameters such as pressure and speed of the injection molding machine, combined with high-precision molds. It is suitable for most products with high requirements on dimensional and surface quality, such as precision plastic gears.

Micro-foam precision injection molding: It uses supercritical fluid as a foaming agent to form micro-bubbles of 1 to 100 microns, which are molded in a low-pressure environment. The dimensional accuracy can reach 0.01 to 0.001 mm or even higher. The mechanical properties and stability of the products are better, suitable for special fields such as aerospace.

Injection compression molding: It combines injection and compression processes. The mold is not closed at first, and then pressure is applied after injecting raw materials for molding. It can improve the surface quality and dimensional accuracy of thin-walled products and is often used in the production of mobile phone shells and other products.

Divided by product application fields, there are also different situations.

Electronic field: Mainly used for precision structural parts such as mobile phone middle frames and camera brackets. These parts need to meet high dimensional accuracy and good mechanical properties to adapt to the miniaturization needs of electronic products.

Automotive field: Covering interior and exterior parts such as instrument panels and rearview mirror shells, as well as plastic parts in the engine compartment, which need to have high strength, high temperature resistance and other characteristics.

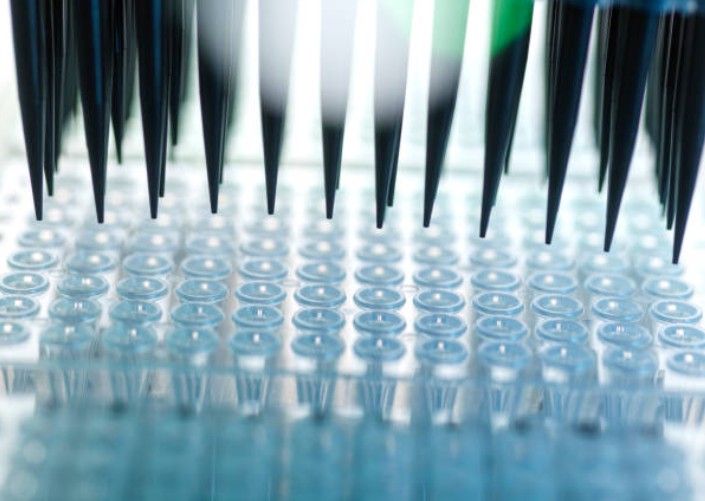

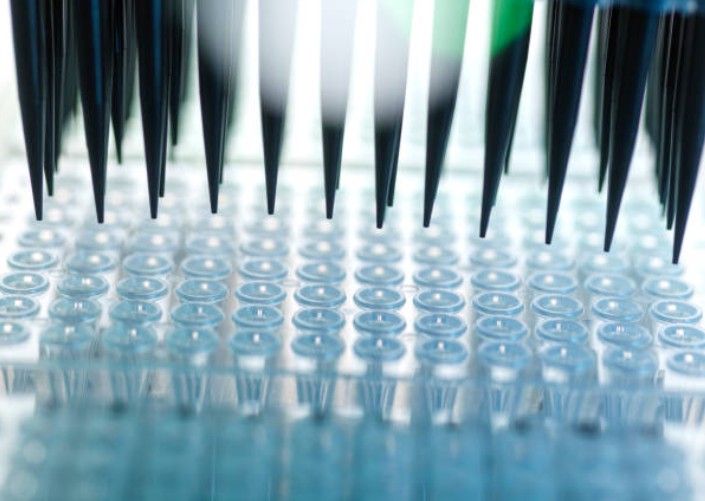

Medical field: Used for producing medical device parts such as syringe barrels and pacemaker shells, which require extremely high dimensional accuracy, and the materials used must have biocompatibility to ensure safe use.

III. Key Factors Affecting Precision Injection Molding

The characteristics of plastic materials are one of the important factors. Different materials have great differences in shrinkage rate and fluidity. Crystalline plastics such as PP and PE have large shrinkage rates, which easily lead to dimensional deviations; while non-crystalline plastics such as PC and PS have smaller shrinkage rates, but their fluidity may be poor.

For high-precision products, engineering plastics with small shrinkage rates, such as PEEK, are usually selected, and the impact of shrinkage is compensated by adjusting process parameters.

The performance of injection molding equipment is also crucial. The manufacturing accuracy of the equipment and the stability of the control system play a key role. Advanced models are equipped with high-precision sensors and intelligent systems, which can collect data in real time and automatically adjust parameters.

Servo motor drive is more precise in control than traditional hydraulic drive, and the uniformity of clamping force will also affect the dimensional accuracy of products.

Mold design and production cannot be ignored either. The mold is the key to determining the dimensional tolerance of products. During design, factors such as the shape of the product and material characteristics need to be considered.

In the production process, high-precision processes such as EDM are adopted, high-performance mold steel is selected, and the cooling system is reasonably designed to reduce product deformation.

IV. Development Trends of Precision Injection Molding in the New Era

Intelligent production is an important trend. By integrating control algorithms and Internet of Things technology, equipment can realize self-optimization and remote monitoring, thereby improving production efficiency and product quality.

Miniaturized manufacturing is also advancing. To meet the needs of the electronic and medical fields, relevant technologies are continuously developed, capable of producing millimetre or even micron-level components, such as micro gears and microfluidic chips.

Environmental protection development has also received increasing attention. Degradable materials such as PLA have been promoted, and environmentally friendly processes such as micro-foaming have been widely used to reduce material consumption and pollution. Green technologies have also been adopted in the mold manufacturing process.