The Application and Challenges of Superalloys in Precision Injection Molds

Based on iron, nickel, or cobalt, high-temperature alloys work long-term under stress at over 600°C. Nickel-based alloys, with comprehensive performance, are most widely used in precision molds.

Core properties: Maintain high mechanical performance at high temperatures to resist injection pressure; withstand thermal cycles to reduce cracks; resist chemical corrosion; achieve high-precision forming through specific processes.

Precision injection molds face harsh environments where ordinary materials wear or deform easily. High-temperature alloys ensure long-term stability and improve part precision, making them ideal for high-end molds.

In electronics, for connectors and chip packages requiring ±0.01mm precision, high-temperature alloy molds maintain stability in mass production, suitable for 5G devices.

In automotive manufacturing, for engine components working above 150°C, these molds resist wear from glass fiber-reinforced materials (e.g., PA66+GF30) and thermal shocks.

In medical devices, treated high-temperature alloys form non-toxic oxide layers, meeting biosecurity requirements for precision parts like infusion connectors.

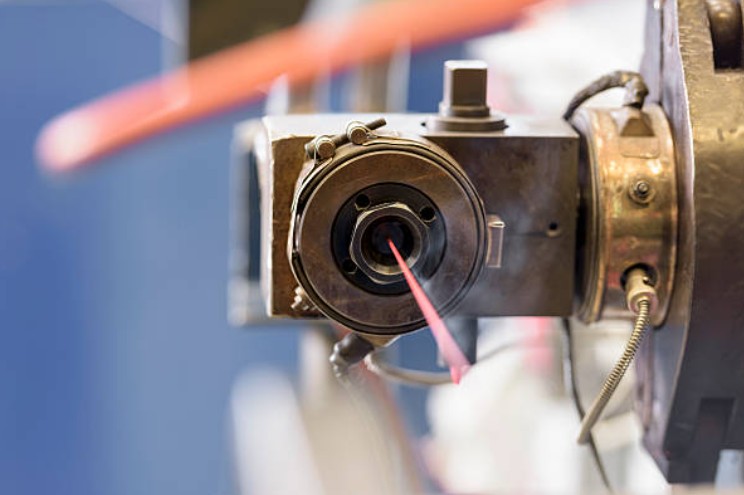

In aerospace, they handle PEEK molding at 380°C, accurately replicating complex structures for lightweight components.

CAE simulation optimizes water channels and cavity structures (e.g., conformal cooling for large curved molds, controlling temperature fluctuation within ±3°C).

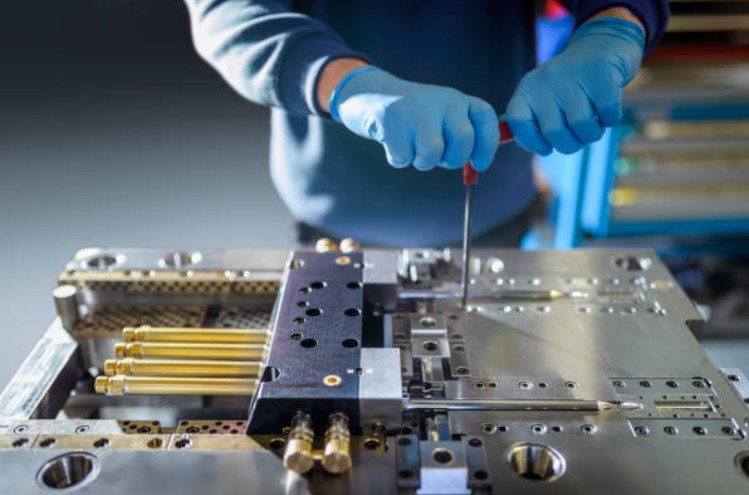

Precision machining: EDM with copper electrodes achieves Ra0.05μm surface roughness; 5-axis milling (spindle >20000r/min) controls edge precision to 0.02mm, limiting flash to <0.03mm.

Surface treatment: PVD-prepared 3-5μm TiAlN coatings raise hardness to over HV3000, improving wear resistance 3-5 times and reducing melt adhesion.

High costs: Raw materials cost 5-8 times that of ordinary mold steel; rapid tool wear increases manufacturing expenses, limiting small-batch applications.

Long processing cycles: Cutting efficiency is 30%-50% of ordinary steel, extending complex mold production by 2-3 times.

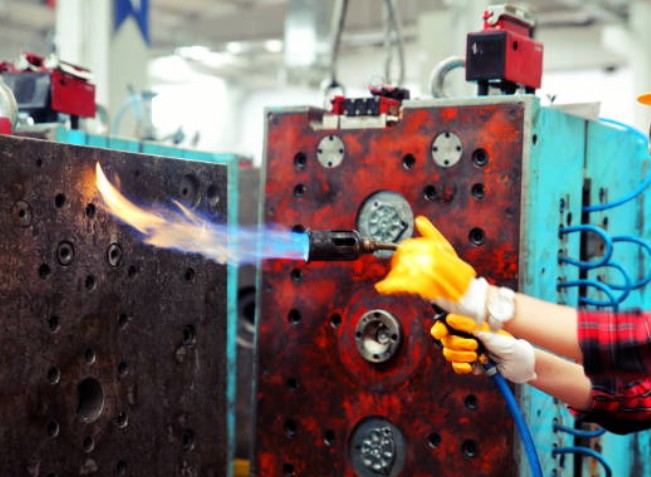

Difficult repairs: Welding requires inert gas protection; post-weld intergranular corrosion makes local wear repair costly and less repairable.

Composite materials: Combining high-temperature alloys with Al?O? ceramic coatings enhances wear resistance while reducing alloy usage.

Smart integration: Digital twins monitor parameters, predict wear, and optimize maintenance to improve utilization.

Green processing: Ultra-high-pressure water jet cutting reduces tool wear; low-temperature minimum quantity lubrication cuts energy use and pollution.