In the complex architecture of electronic devices, precision injection-molded parts serve as vital "screws"—though small, they are indispensable. With precise dimensions and excellent performance, they underpin the stable operation, lightweight design, and functional expansion of electronic devices. Here’s a concise breakdown of their diverse categories:

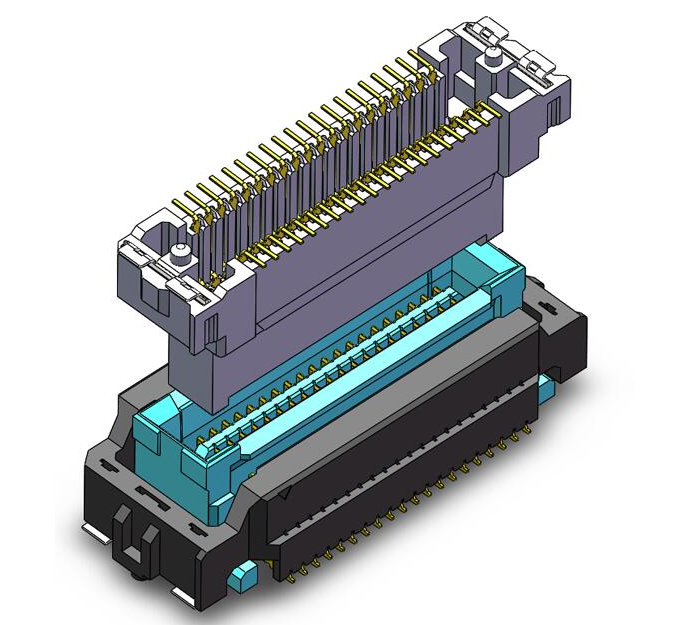

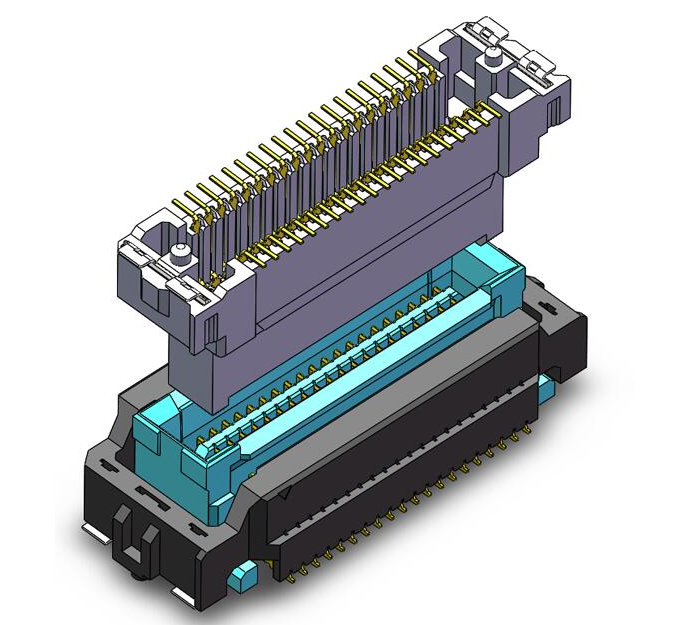

Connectors act as circuit "bridges" in electronic devices, enabling power and signal transmission. Precision injection molding imparts critical insulation, support, and fixation functions to these components.

Used to link different circuit boards (e.g., motherboards and expansion cards like graphics or sound cards), these parts are typically molded from liquid crystal polymer (LCP). LCP’s high fluidity and dimensional stability allow for ultra-fine pin pitches (as small as 0.3mm), ensuring stable signal transmission and minimizing crosstalk and impedance mismatch.

In smartphones and tablets, wire-to-board connector parts secure connections between battery/camera flex cables and motherboards. Made from polybutylene terephthalate (PBT)—a cost-effective, insulating material—they are precision-molded to fit cable specifications, preventing loose connections from vibration or bending.

Essential in wireless devices (e.g., 5G base station antennas and RF modules), RF connector parts require low-dielectric, low-loss materials like polyphenylene sulfide (PPS) due to high-frequency operation (up to millimeter waves). Precision molding ensures accurate insulation between inner and outer conductors, reducing signal attenuation.

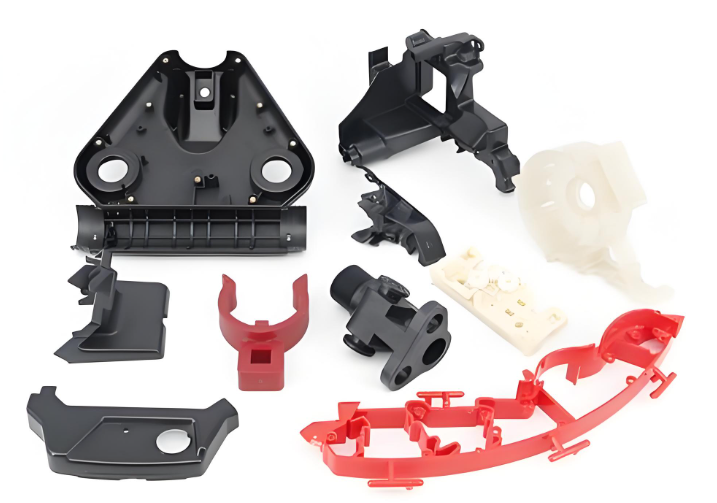

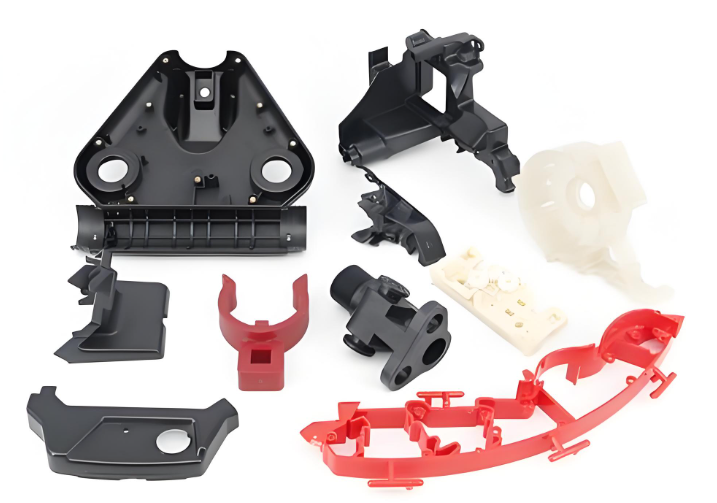

These parts provide robust internal support to protect delicate electronics and withstand external impacts.

Laptop and gaming console frames, molded from glass fiber-reinforced polycarbonate (PC+GF), offer impact resistance, transparency (for light-transmitting designs), and strength. Precision molding ensures exact dimensions for mounting holes and slots, matching internal components seamlessly.

In smartphones, brackets for chips and camera modules are molded from polyoxymethylene (POM), valued for its rigidity and wear resistance. They secure components via snaps or screw holes, preventing displacement during use or transport.

As device performance rises, heat dissipation parts like fan frames and heat sink mounts become critical. Fan frames, molded from nylon (PA), maintain stability at high speeds, while heat sink mounts use thermally conductive plastics (e.g., PP with graphite/carbon fiber) to ensure tight heat transfer.

For electronic devices with mechanical motion, these parts enable power transmission and motion control.

Fan gear sets in computers, molded from LCP or POM, ensure smooth, low-noise operation. LCP offers dimensional stability, while POM’s self-lubrication minimizes wear, supporting long-term high-speed rotation.

Though less common, gears in optical drives (for professional equipment or retro gaming consoles) are molded from PC or PA. PC’s impact resistance and PA’s fatigue resistance maintain precision during frequent start-stop cycles.

Critical for imaging quality in cameras and projectors, these parts leverage precision molding for optical performance.

Non-spherical lenses in camera lenses, now often molded from PMMA or cyclic olefin copolymer (COC), replace costly glass. Precision molding achieves nanometer-level surface roughness, reducing aberrations and enhancing image clarity.

Brackets for camera/projector lenses, molded from polyetheretherketone (PEEK), ensure stable component positioning across temperature/humidity changes, maintaining optical system reliability.

From connectors to structural supports, transmission gears to optical components, precision injection-molded parts permeate every corner of electronic devices. As electronics evolve toward miniaturization and intelligence, ongoing innovations in materials and molding processes will continue to drive advancements, enabling lighter, smarter, and more powerful devices.