Precision Injection Molding: Key Processes and Technical Specifications

2025-06-16 10:51:04

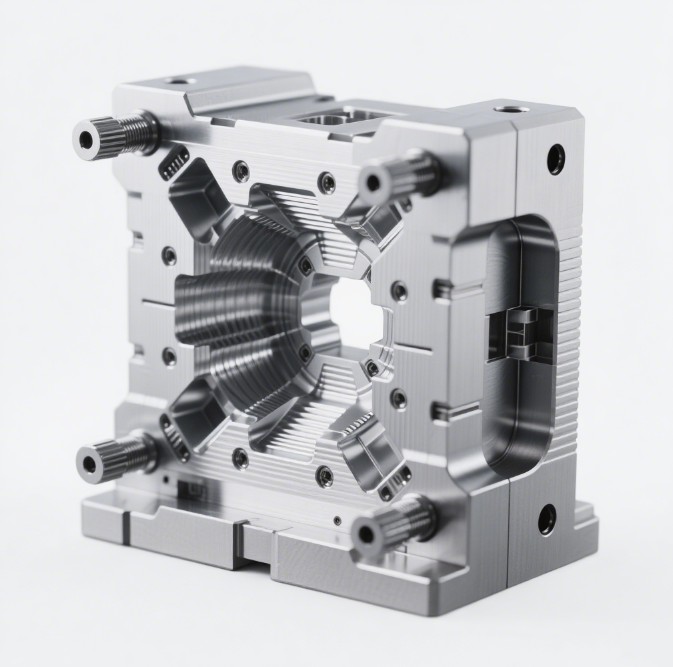

Precision Injection Molding

Material Selection

Engineering plastics for precision molding require high mechanical strength, dimensional stability, creep resistance, and environmental stress cracking resistance. Common materials include:

Polycarbonate (PC): Applied in optical lenses and electronic enclosures for its transparency, heat resistance, and dimensional stability.

Polyoxymethylene (POM): Suitable for precision gears and mechanical parts, featuring high rigidity, low friction, and fatigue resistance.

Drying Treatment

Moisture in plastic pellets can cause surface defects like silver streaks and bubbles, and reduce mechanical properties. For hygroscopic materials such as Nylon (PA), drying parameters are critical:

Temperature: 80–120°C

Duration: 2–4 hours

Moisture content: ≤0.1%

Mold Precision Design

Cavity dimensions are calculated based on shrinkage rates, influenced by:

Gate type, location, and distribution

Material crystallization orientation (anisotropy)

Part geometry, size, and distance from the gate

Tolerance: ≤±0.005 mm

Surface roughness: Ra 0.1–0.05 μm

Gate Design

Pin-point gate: For high-precision parts with minimal gate marks.

Edge gate: Versatile for various shapes, requiring careful placement to avoid weld lines.

Submarine gate: Hidden within the mold, suitable for aesthetic components.

Cooling System Design

Maintain uniform mold temperature (±1°C variation) to minimize shrinkage and warpage.

Use circulating water channels around the cavity.

For complex molds, adopt zone-controlled cooling for uneven heat distribution.

Mold Manufacturing Processes

Electrical Discharge Machining (EDM): Achieves ±0.01 mm precision for complex shapes.

Wire-cut EDM: Cuts intricate features with ±0.005 mm accuracy.

Grinding: Ensures surface flatness within ±0.002 mm.

Injection Speed

Apply segmented injection for complex molds:

Stage 1: Slow filling (30% speed, 40 bar) to avoid jetting.

Stage 2: Medium speed for intricate sections.

Stage 3: Fast filling to 95% of cavity volume.

Stage 4: Slow buffer for packing.

Packing Pressure and Time

Injection Pressure

Barrel Temperature

PP: 180–230°C

PC: 270–320°C

Mold Temperature

Crystalline plastics (e.g., PE, PP): Higher temperatures for uniform crystallization.

Amorphous plastics (e.g., PS, PMMA): Optimized for flow and surface finish.

Injection System Precision

Screw diameter and L/D ratio tailored to part size.

Shot volume accuracy: ≤±0.5%.

Pressure control: ≤±1 MPa fluctuation.

Clamping System Rigidity

Control System Stability

Digital control with real-time monitoring of speed, pressure, and temperature.

Fault diagnosis and alarm functions.

Annealing

Moisture Conditioning

Surface Treatment

Conclusion

Precision injection molding requires strict control across material selection, mold design, process parameters, equipment, and post-processing. Optimizing each stage ensures dimensional accuracy, surface quality, and mechanical performance for high-value applications.