What is glass fiber reinforced plastic?

Glass Fiber: It is the main load-bearing material, featuring high strength and low weight with outstanding performance. It can improve the low-temperature impact resistance and stiffness of the composite material, and reduce the low-temperature shrinkage of the polymer matrix. Common types of glass fiber include E-glass fiber and S-glass fiber. E-glass fiber has good electrical insulation and corrosion resistance, and is the most commonly used one. S-glass fiber has higher strength but relatively higher cost.

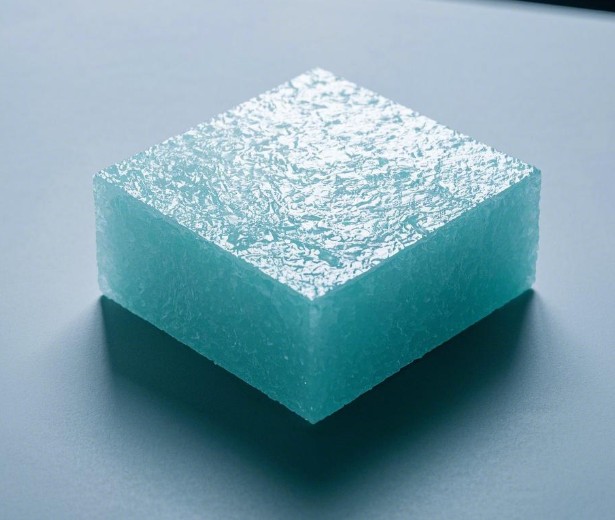

Synthetic Resin: It bonds the fibers together and plays a role in protecting the fibers. When the composite material is under load, the polymer matrix evenly distributes the stress to the fibers through shear action, making the fibers stressed evenly. At the same time, it can endow the products with certain flexibility and chemical stability. Commonly used synthetic resins include polyester resin, epoxy resin, phenolic resin, etc. Polyester resin has a lower cost and good processing performance. Epoxy resin has high bonding strength, good corrosion resistance and heat resistance. Phenolic resin has higher heat resistance and flame retardancy.

Advantages

Lightweight and High Strength: Its relative density is between 1.5 and 2.0, only 1/4 to 1/5 of that of carbon steel, but its tensile strength is close to or even exceeds that of carbon steel, and the strength can be comparable to that of high-grade alloy steel. It is widely used in aerospace, high-pressure vessels and other products that require weight reduction.

Good Corrosion Resistance: It has good resistance to the atmosphere, water, and acids, alkalis, salts at general concentrations, as well as a variety of oils and solvents. It has been widely applied in all aspects of chemical anti-corrosion, and is replacing materials such as carbon steel, stainless steel, wood, and non-ferrous metals.

Good Electrical Performance: It is an excellent insulating material and can be used to manufacture insulators, still maintaining good electrical insulation performance under high frequency.

Good Thermal Performance: Its conductivity is low, being 1.25-1.67KJ at room temperature, only 1/100 to 1/1000 of that of metals. It is an excellent thermal insulation material. In the case of instant ultra-high heat, it is an ideal thermal protection and ablation-resistant material.

Excellent Processability: The molding process can be selected according to the shape of the product, and the process is simple, allowing one-time molding and enabling the manufacture of products with complex shapes.

Good Designability: Materials can be fully selected according to the needs to meet the performance and structural requirements of the product. For example, by adjusting the content of glass fiber, the layering method, and the type of resin, different mechanical, physical and chemical properties can be achieved.

Disadvantages

Low Elastic Modulus: It is 2 times larger than that of wood but 10 times smaller than that of steel. Therefore, in the product structure, it often feels that the rigidity is insufficient and it is easy to deform. Usually, it needs to be made into a thin-shell structure, sandwich structure or supplemented by high-modulus fibers or stiffeners.

Poor Long-term High-temperature Resistance: Generally, it cannot be used at high temperatures for a long time. The strength of FRP with general polyester resin will decrease significantly above 50 degrees Celsius.

Aging Phenomenon: Under the action of ultraviolet rays, wind, sand, rain, snow, chemical media, mechanical stress, etc., its performance is likely to decline.

Low Interlaminar Shear Strength: The interlaminar shear strength is borne by the resin, so it is relatively low. The interlaminar bonding force can be improved by selecting the process, using coupling agents, etc., and the interlaminar shear should be avoided as much as possible in the product design.

Hand Lay-up Molding Technology: It is a low-pressure or pressureless molding technology that uses room-temperature curing thermosetting resins such as unsaturated polyester and epoxy resin to bond glass fiber and its fabrics and other reinforcing materials together. The main process is to alternately brush or spray a layer of resin adhesive on the mold coated with a release agent, and then lay a layer of fiber reinforcing material. Repeat this operation until the product size requirements are met.

Spray Molding Technology: Developed from the hand lay-up molding process, it uses a spray gun to cut and disperse the glass fiber, and makes the fiber and the atomized resin adhesive mix in space, then sprays them onto the mold, and finally compacts them with a pressure roller and cures them to obtain the product.

Compression Molding Technology: Preheat and preform the molding compound, then load it into the preheated mold coated with a release agent, press it, demold it, and get the finished product after trimming.

Reaction Injection Molding Technology: Inject the metered and mixed liquid resin into the mold, and it undergoes a chemical change and cures into a product of a certain shape in the mold.

Pultrusion Molding Technology: Pass the continuous glass fiber bundles or cloth tapes impregnated with resin adhesive through the molding die for molding, and cure them in the die or the heating furnace. Under the pulling force of the traction mechanism, continuously pull out the fiberglass profiles of infinite length.

Construction Industry: It is used in the fields of structural reinforcement, building formwork, wall panels, reinforced concrete, bridge decks, road surfaces, etc.

Transportation Field: In automobiles, it is used for components such as the body shell, hard top, sunroof, headlight reflectors, front end brackets, bumper frames, engine valve covers, intake manifolds, etc. The locomotive heads and interior decoration parts of high-speed trains mostly use fiberglass reinforced plastic materials. In the field of boats, fiberglass fishing boats, yachts, sailboats, etc. have been widely used.

Industrial Equipment Field: It can be used to make various pultruded profiles, gratings, etc., such as doors and windows, grating profiles, ladders, cable trays, etc., and can also be used to manufacture pipes and tanks, such as fiberglass FW process pipes, sand-filled pipes, high-pressure pipes, etc.